- Group

- A specialist for 30 years in producing promotional packs for the hygiene and care markets for brands and contract packers, using a unique compact technology.

- A flexible machine that adapts to multiple bundle specifications

- A modularity that meets the needs of delayed differentiation

- Quality and non-degraded performance on unit cycle at 240 cpm

- Features

- Options

- Specifications

- Packaging

Home Clé en main Combishrink® MP120 – AI35

Combishrink®

MP120 - AI35Boost your sales by offering bundles with an rPET sleeve

Features

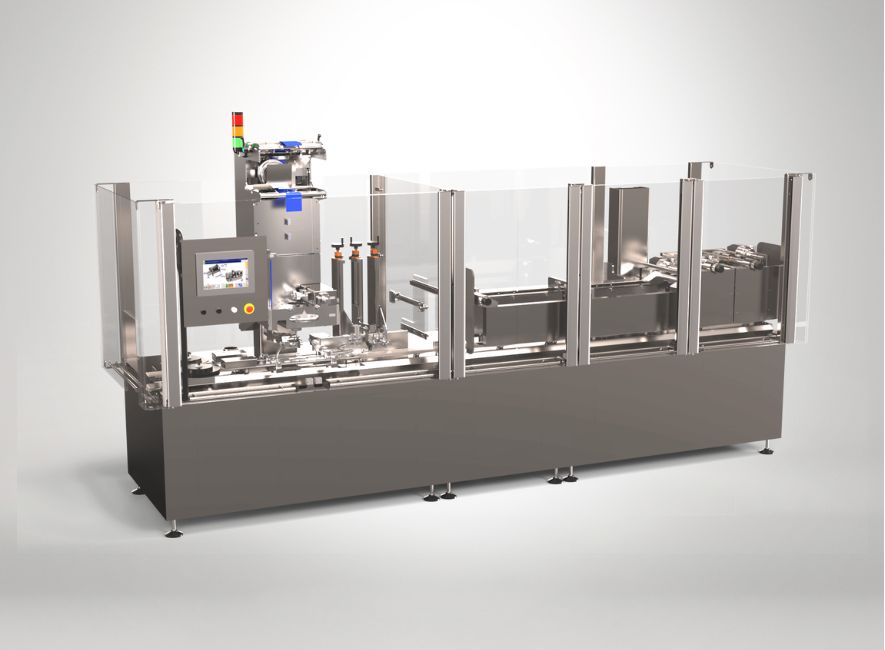

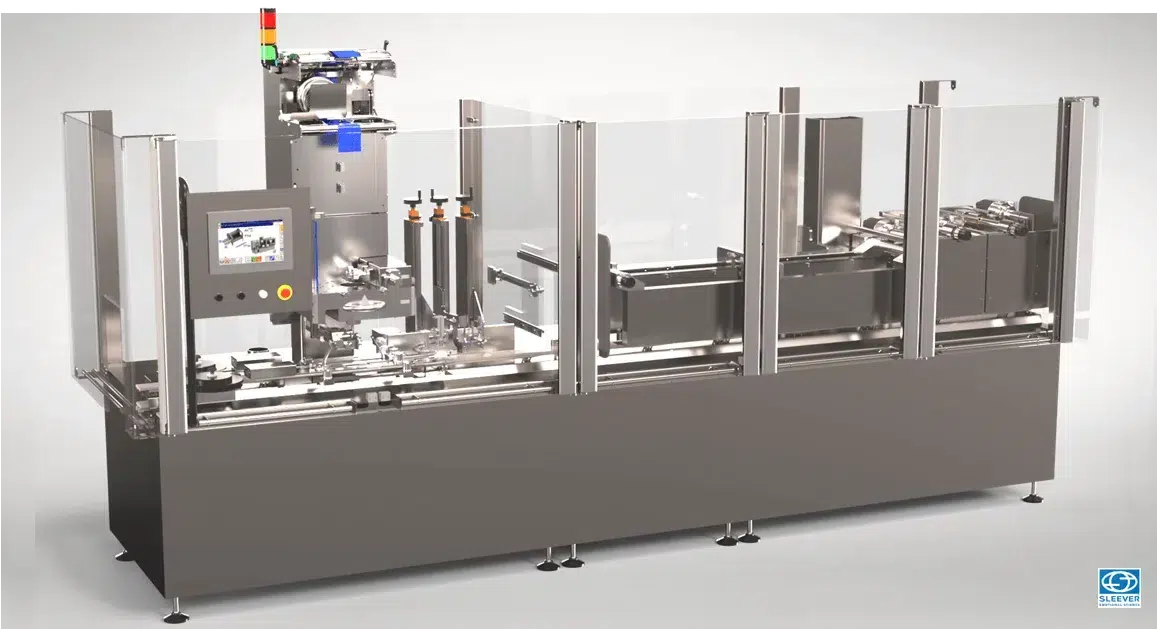

A compact design, suitable for inline or offline production

A machine design made for hygiene and care products

An easy-to-use, monobloc, all-stainless steel inline or offline installation whose design, compactness, transparency, easy access and cleaning meet the expectations of brands and co-packers who produce promotional packs on a daily basis.

Modularity for eco-designed and attractive packs

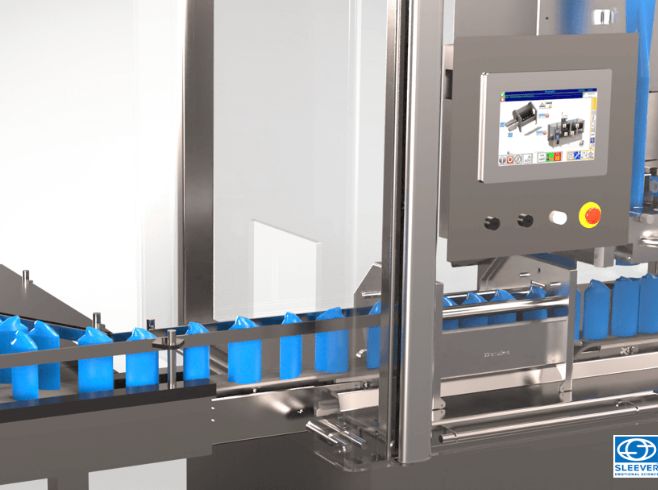

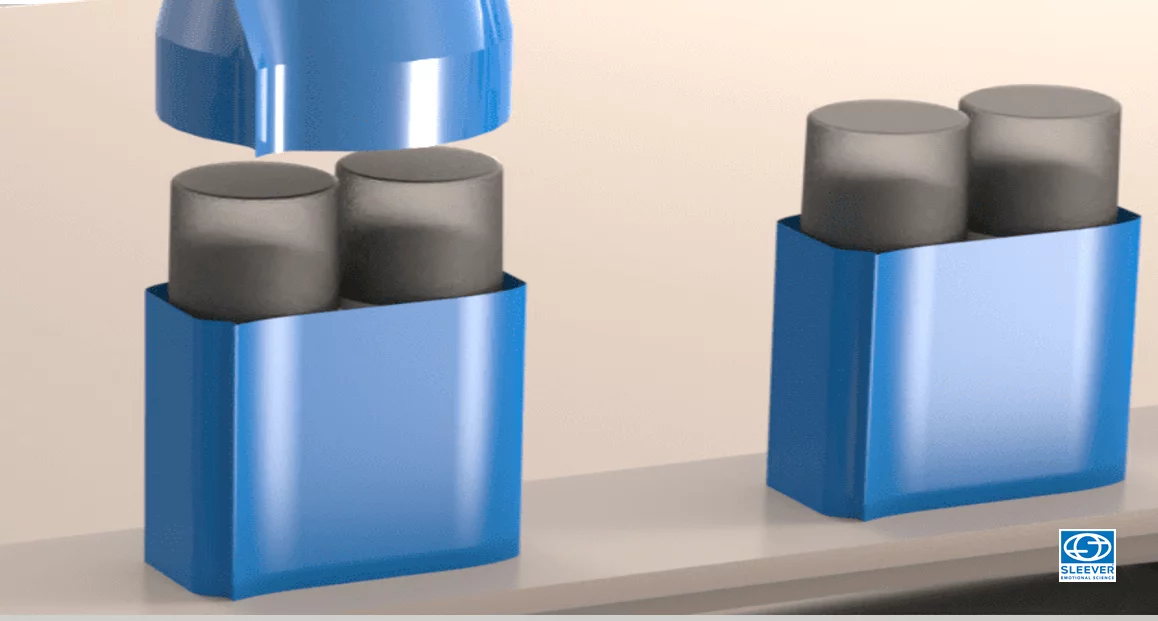

Flexibility for multiple configurations

A modular design that meets promotional bundle specifications such as handling in all directions: one behind the other, back to back, grouped, oriented, in multiple configurations from 1X2 to 1X4, of various materials, shapes and capacities. All this is done with an optimized facing that doesn’t take up more shelf space.

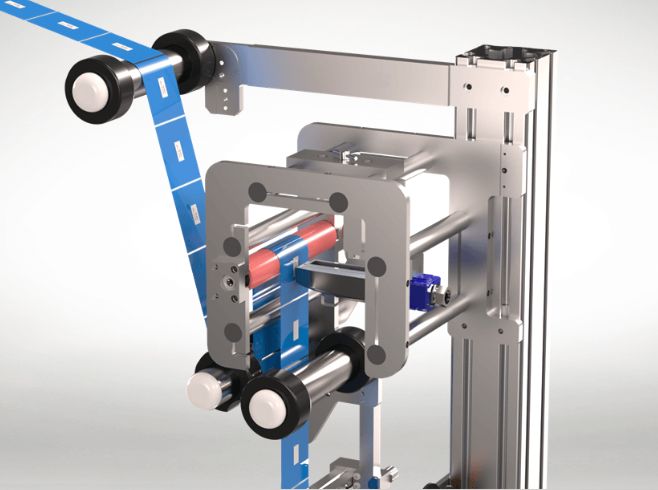

Personalization in all its forms

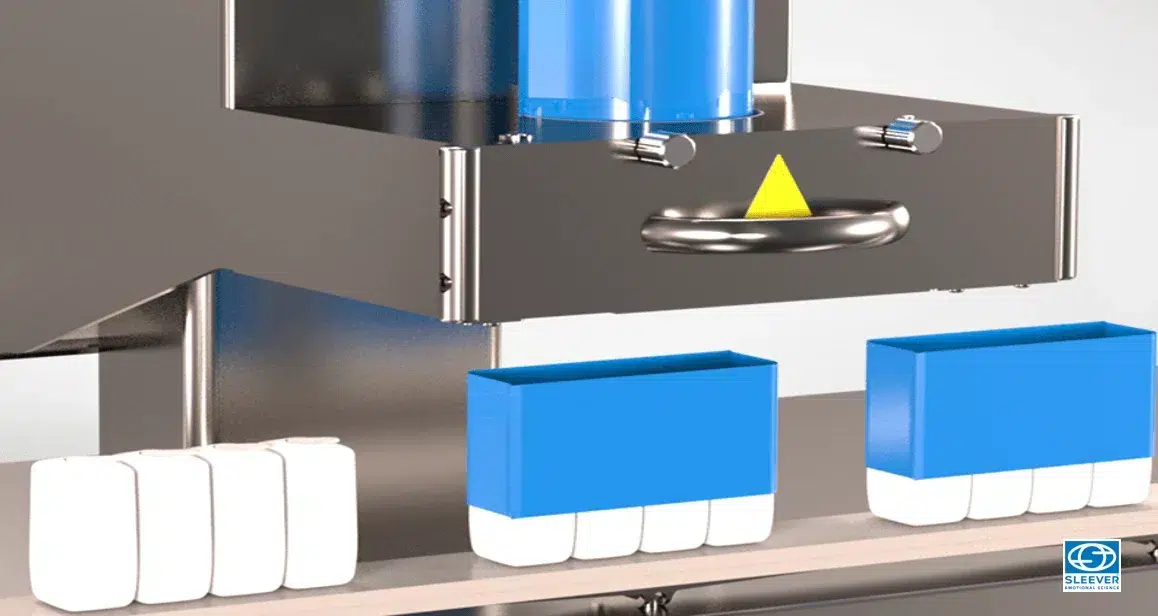

Delayed differentiation for promotional packs

Different modules allow for the enhancement of the promotional offer, such as labeling which allows for couponing, micro-perforation inline to allow for quick separation, coding which allows for the creation of a barcode for the bundle inline and marking which allows for traceability for bundle identification and the use-by date.

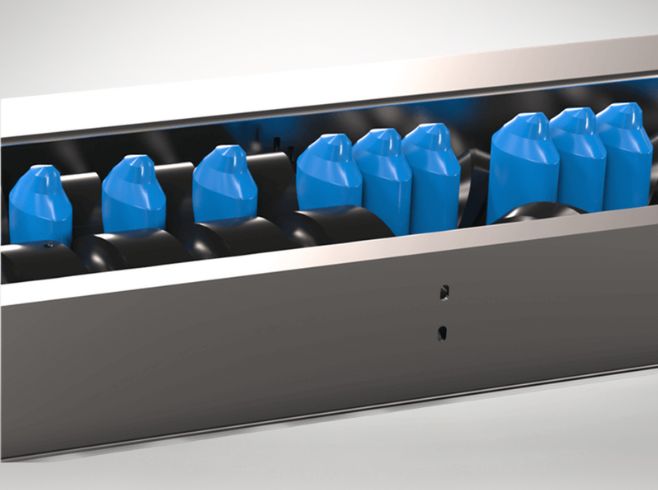

Bundle resistance quality without compromising on performance

A unique infrared technology plus hot air for those who do not have a central steam unit

An infrared plus hot air technology that is suitable for products that cannot use steam shrink technology such as cosmetics, beauty and health products. A unique bundle quality that resists dislodging, non-degraded performance at 300 cpm in unit speed, with 360° distortion-free rendering across the height and width of the bundle.Options

Shrink-sleeve orientation module

The assurance of a well-oriented bundle facing

Mobile tool trolley for the proximity and security of your tools

Optimize your format changeover times

A solution for large formats, in number of units or with a large diameter

An offer tailored for large formatsSpecifications

* Non contractual information

Machine

Conveyor height980 +/- 50 mmSpeed120 bpmCutting diameterFrom 100 to 210 mmSteam consumption35 kWMachine length4600 mm

Packaging

MaterialsGlass, PlasticsShapesCylindrical, oval, square, specialSizesfrom 100 ml à 4kgProducts diameterfrom 60 to 205 mmProducts heightfrom 90 to 300 mm

Sleeves

ApplicationmultipacksType of filmsPET, RPET,OPSFilms thicknessfrom 50 à 75 micronsFinishingneutral, printed...Markets & Packaging

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.Statistics

The technical storage or access that is used exclusively for statistical purposes. The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.