- Group

- Your packaging decorated with an integral sleeve label for the food powder, cosmetic and pharmaceutical markets

- A modular machine designed for medium to high production rates, with optimized energy consumption

- An ergonomic designed magazine for autonomy and operator friendly

- Features

- Options

- Specifications

- Packaging

Home Clé en main Combiskinner® FB250 – AI58

Combiskinner®

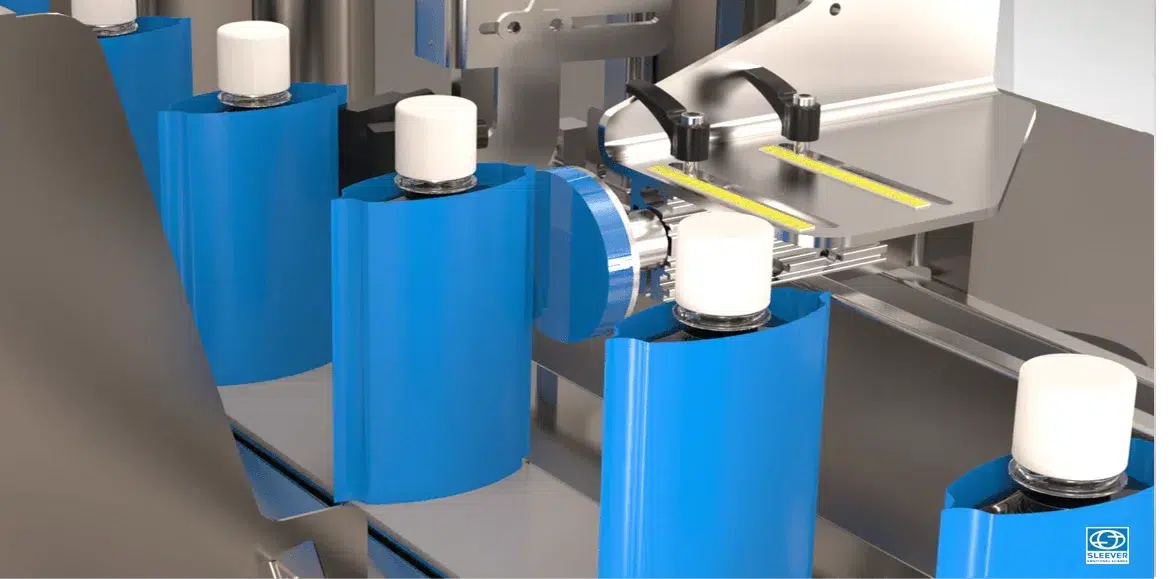

FB250 - AI58Flexible equipment for full body sleeve labeling

Features

Modularity at the service of performance

Modules designed and adapted for speeds of food, health and cosmetics markets

For working at high speed, this machine is equipped with modules that guarantee performance and quality: as the orientation system for complex shapes, and control and ejection system.

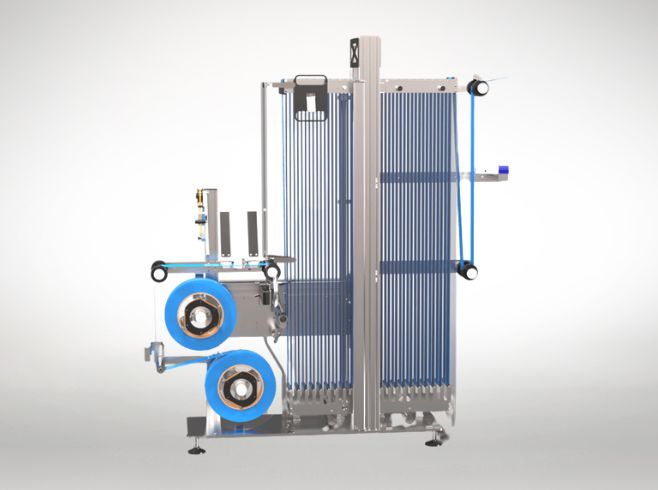

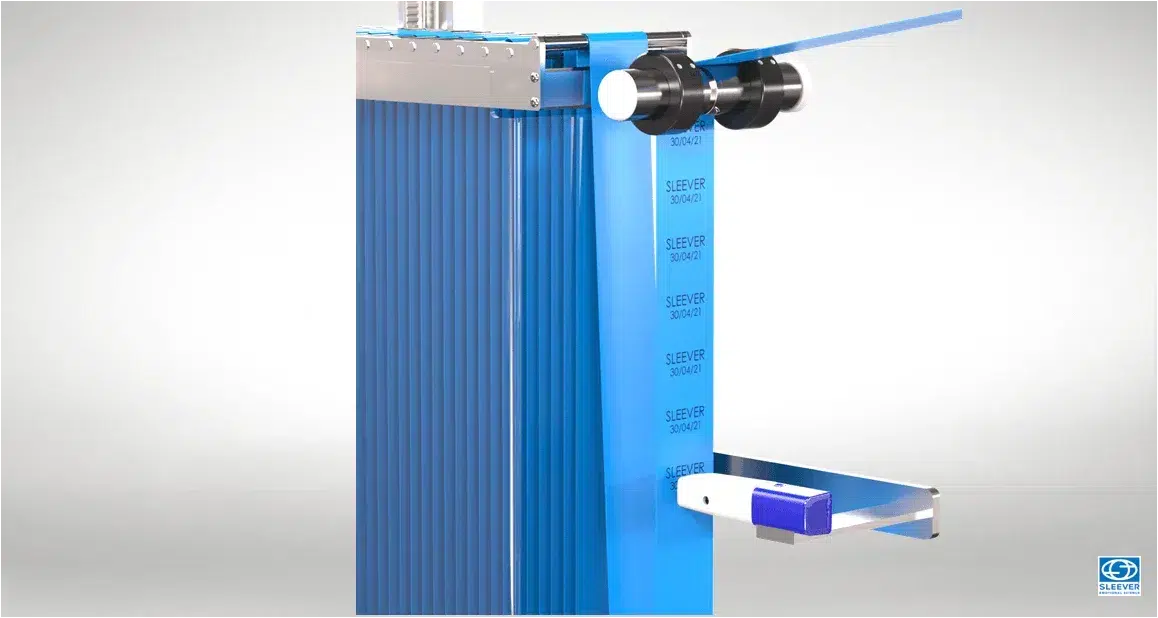

Ergonomic design for quick and easy reel junctions

Ergonomic design for quick and easy junction of reels and a large capacity buffer for autonomy

This large capacity magazine can handle high sleeve application speeds and is designed to accommodate next-generation films. Located outside the machine, it provides easy access to reels, which are positioned at man’s height; the connection table allows quick and error-free junction. The entire system offers autonomy and ergonomics for operator comfort.

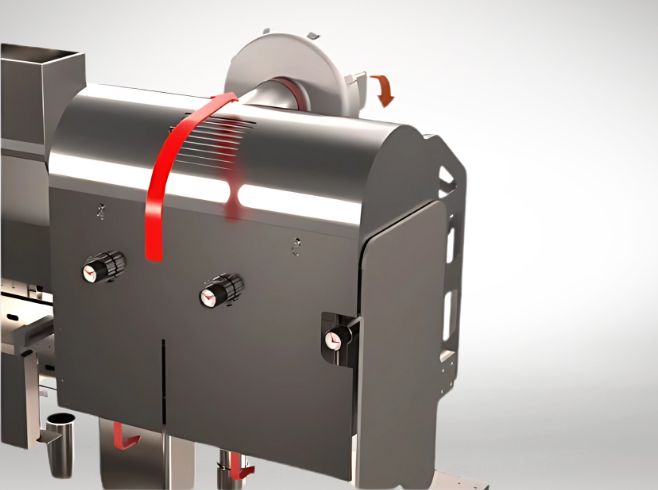

Reduction of heat exchanger consumption by closed loop supply

Energy management to reduce the carbon footprint of your products

This sleeve retraction technology combines several advantages: the infrared technology adjustment, the height-adjustable tunnel and the hot air diffusion system are adapted to each product to optimize energy consumption. We recycle the hot air reintroduced above the heat exchangers from the retraction process to reintroduce it upstream into the heat exchangers. This is a closed loop approach. The hot air nozzles provide only the electrical supplement to reach the set temperature and reduce consumption by 50%.

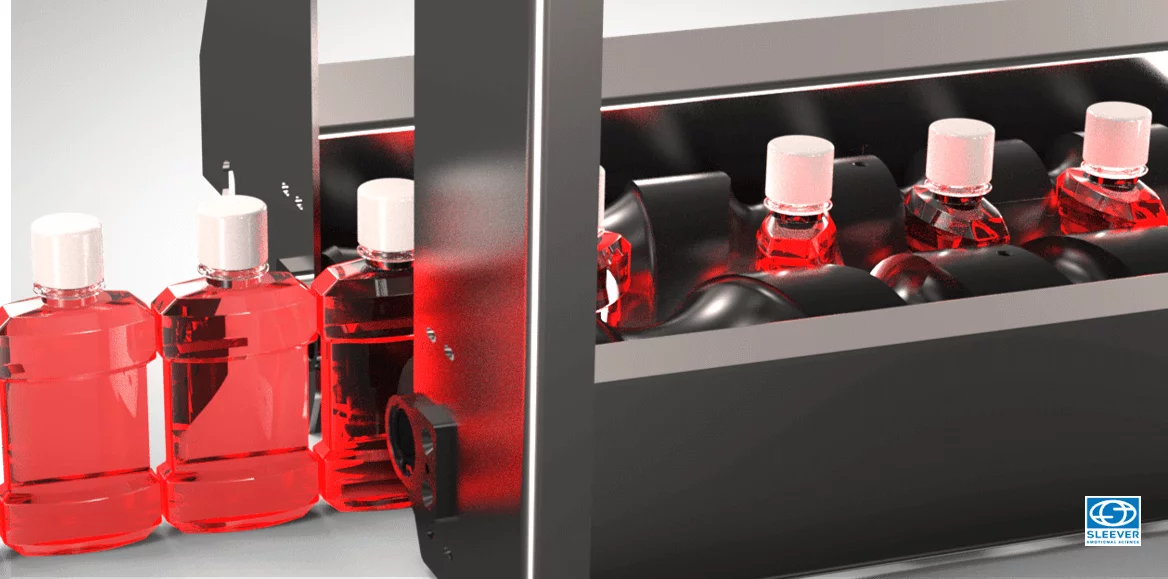

A machine adapted to the new generation of eco-designed sleeves

Innovative technology for the recyclability of your packaging

A machine designed to decorate all full or empty packaging sensitive to moisture: confectionery, health care, and cosmetics. Flexibility of capacity (100gr to 2kg), and shapes (classic and sophisticated).

Options

Orientation module in screws

Ensuring a well-oriented facing

Modular applicator head and shrink tunnel

We have made modularity the secret of your performance

Coding and serialization module

Where traceability and coding unit are required on markets

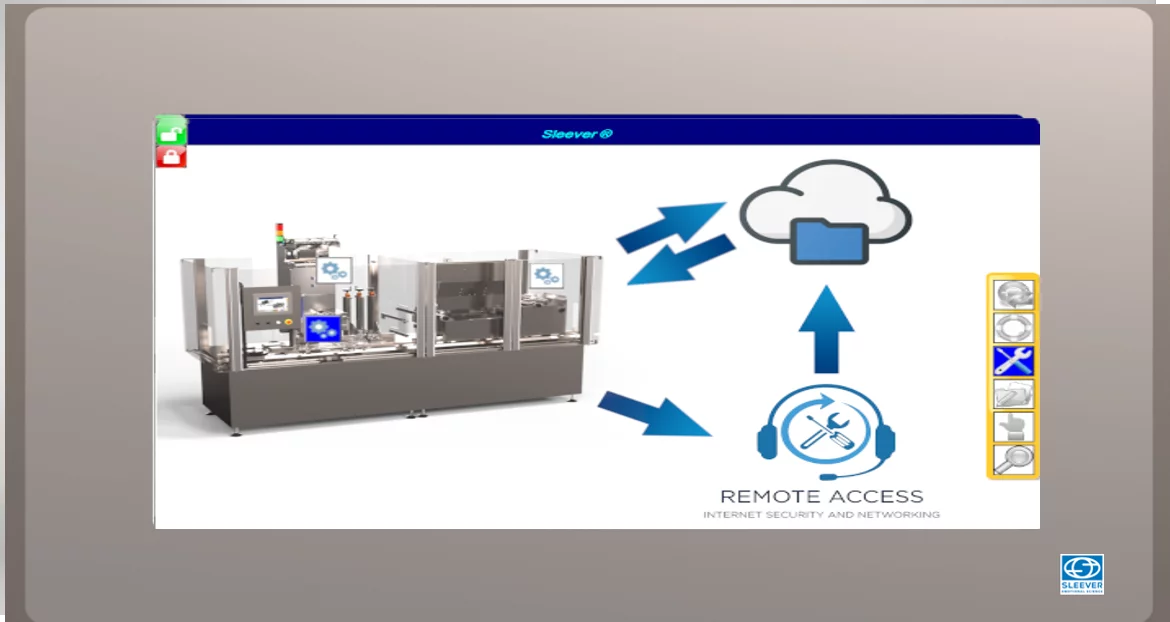

Ethernet communication module

For multiple communication usesSpecifications

* Non contractual information

Machine

Conveyor height980 +/- 50 mmSpeed120 – 250 cpmCutting diameter100 to 130 mmElectrical consumption15 to 40 KW/hMachine length3600 mm

Packaging

ShapesCylindrical , complex shapes...Products diameter45mm to 125 mmProducts height100 mm to 200mmMaterialsPET, glass, PE, PP, metalSizes20 gr – 2 kg

Sleeves

ApplicationFull coveringType of filmsOPS, PET,Films thickness20 – 75 micronsFinishingNeutral, printed effectsMarkets & Packaging

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.Statistics

The technical storage or access that is used exclusively for statistical purposes. The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.