- Group

- A compact equipment adapted to the pharmaceutical market to label medical devices: inhalers, nasal sprays, …

- A modular eco-designed packaging machine specialized for medium production rates that meets pharmaceutical specifications

- Interactive, it allows data feedback and traceability

- A hot air shrink technology adapted to health products

- Features

- Options

- Specifications

- Packaging

Home Specialties Combiskinner Medwear® FB 200 – I43

Combiskinner Medwear®

FB 200 - I43Eco-designed packaging Equipment for medical devices

Features

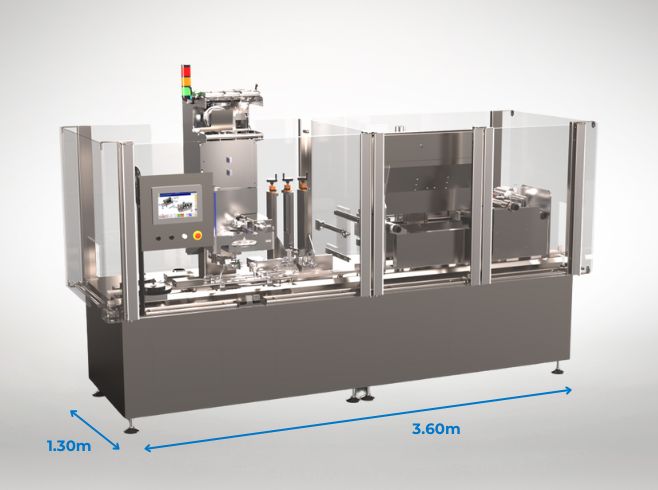

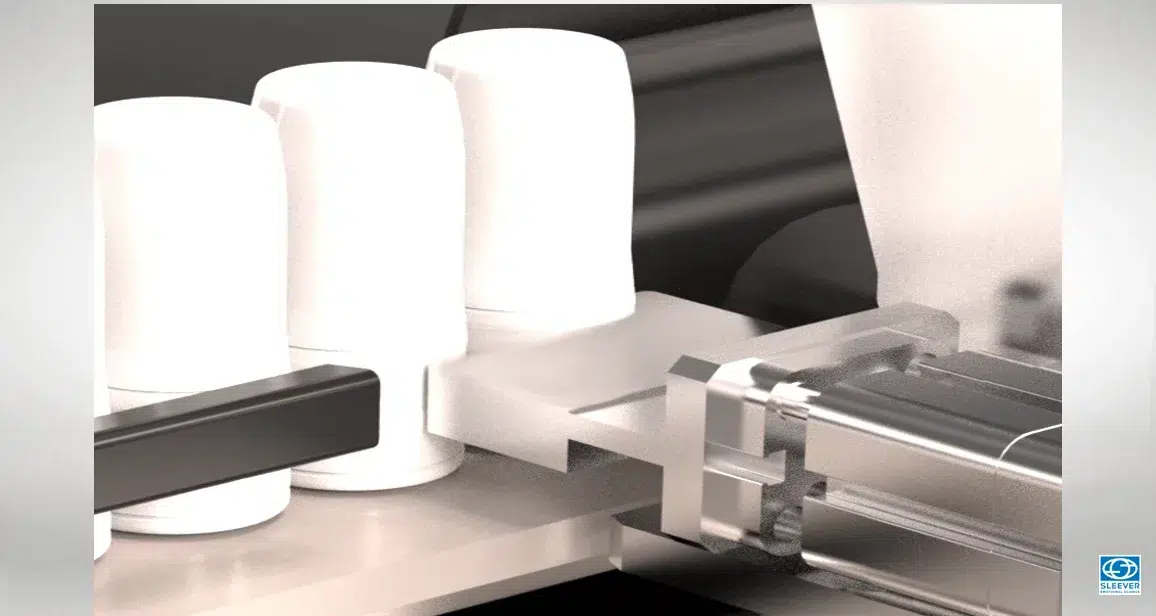

A compact, monobloc structure

Hygiene and safety: a design adapted to medical devices

An equipment designed to meet pharmacy standards: all stainless steel, no retention zone for optimal cleanability and a 360° guarding for operator’s safety. A monobloc structure that integrates the shrink-sleeve application head, the shrinking tunnel and the electrical cabinets for an optimized floor footprint.

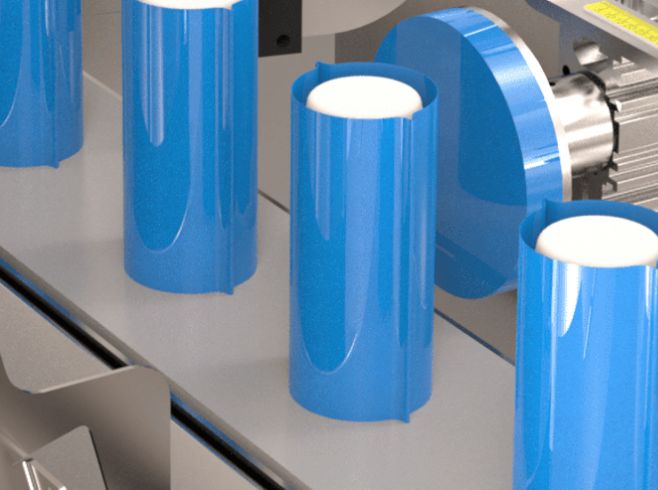

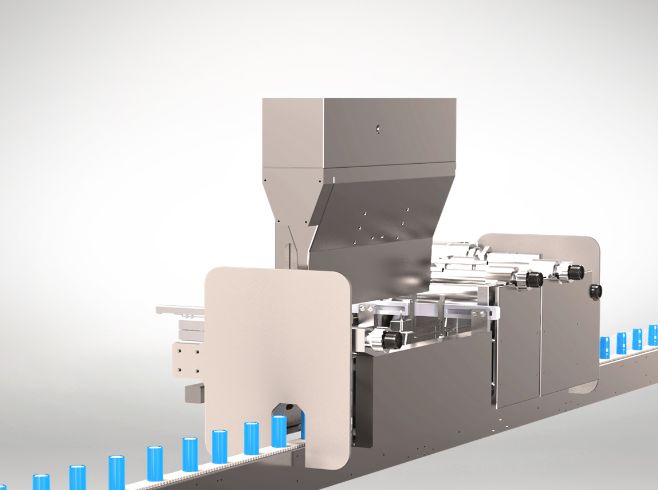

Modules to meet the specific needs of medical devices

Modularity at the service of performance

This machine guarantees performance with modules that meet the characteristics of medical devices: temperature deviation control, ejection module adapted to their format, all while respecting the industry’s average speeds (200 bpm). A servomotor technology allows the use of new generation films to meet the challenges of ecological transition.

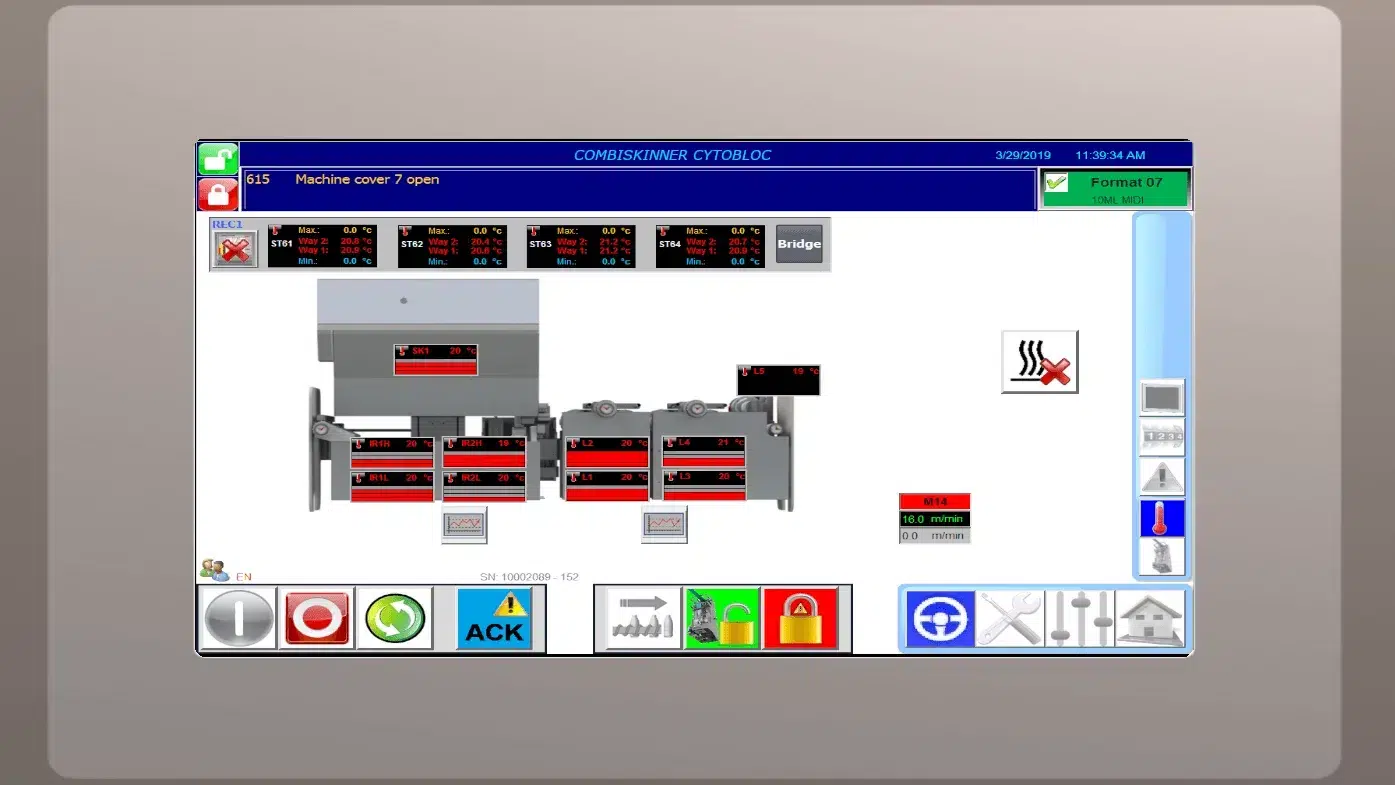

A connected machine

A smart machine for traceability

An equipment including a data recording system to meet the traceability needs of the healthcare applications. It is equipped with an ethernet card allowing to communicate with an external server, to transfer the data recorded during production.

Hot air shrink technology for sensitive products

Mastering energy consumption to optimize carbon footprint, without compromising on the finishing quality

A hot air shrinking technology ensures that sensitive products are not altered during the shrink-sleeve label shrinking phase. Each recipe has its own adjusted and memorized temperature for both the infrared ramps and the hot air nozzles that ensure the finishing. The settings per recipe allow to control and optimize the energy consumption per format.

Options

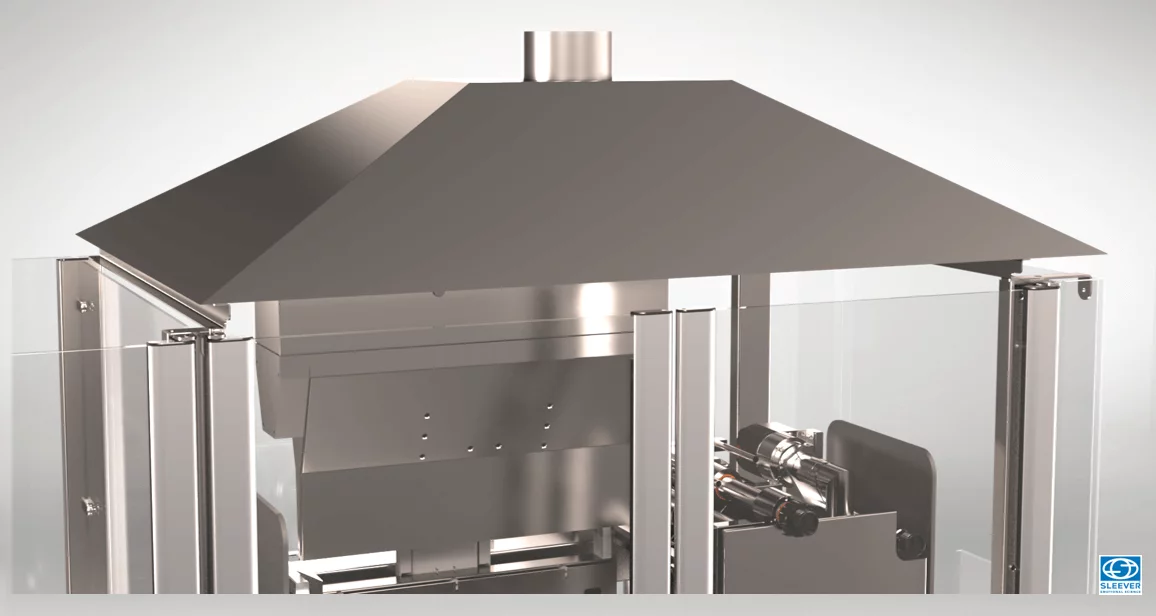

Exhaust hood for temperature control

Controlled temperature for working in a controlled atmosphere

Monitoring and temperature control

The guarantee of a product at the right temperature

Line clearance module

Products protected in case of a machine stop

Blocking of products at machine infeed

Blocking of products without damaging or constraining themSpecifications

* Non contractual information

Machine

Conveyor height980 +/- 50 mmSpeed200 cpmCompressed air100 mmElectrical consumption43 kWMachine length3600 mm

Packaging

PackagingPETShapesCylindrical, square, complex shapes...Products diameter45 to 70 mmProducts height185 – 210 mmSizes20 ml – 1 l

Sleeves

ApplicationFull body with or wihout tamper evidenceType of filmsPET, rPET, OPSFilms thickness30 – 70 micronsMarkets & Packaging

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.Statistics

The technical storage or access that is used exclusively for statistical purposes. The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.