- Group

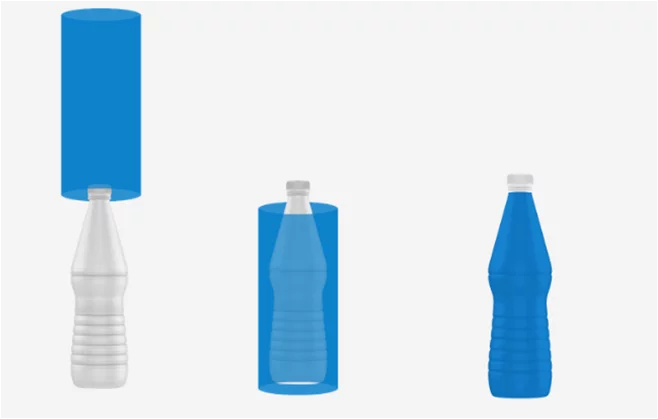

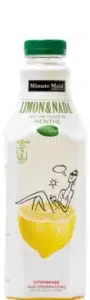

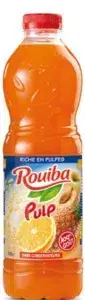

- Your bottles decorated with an integral shrink-sleeve label can enter the PET recycling stream

- A modular machine designed for high production rates

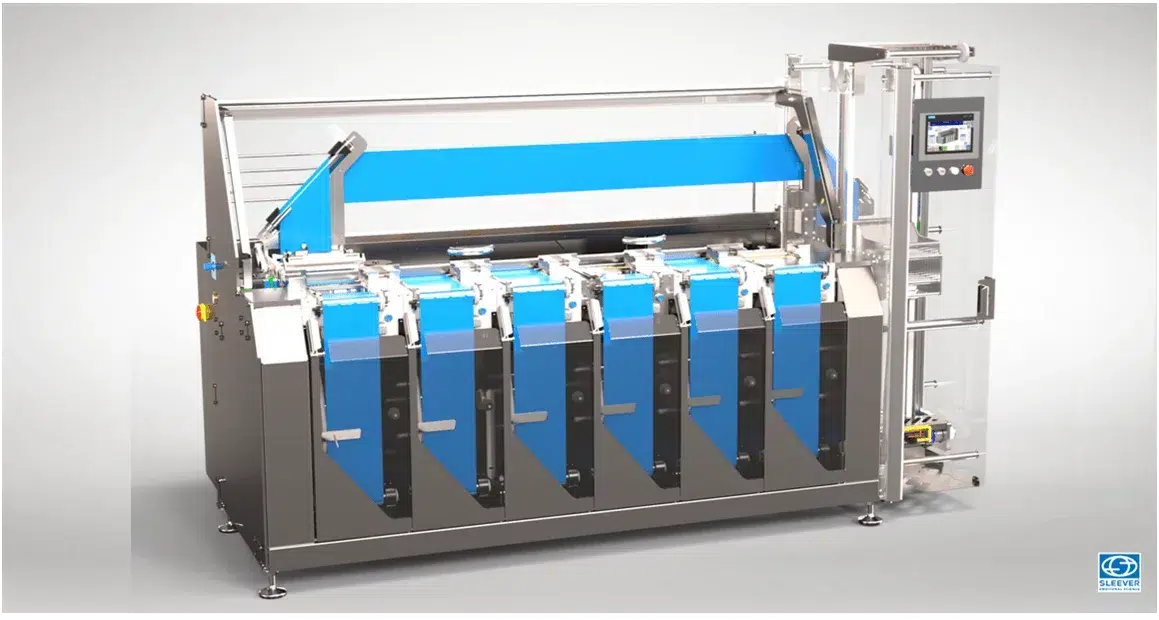

- An ergonomically designed shrink-sleeve unwind unit for the operator’s autonomy and comfort

- Optimized energy consumption for carbon neutrality

- Features

- Options

- Specifications

- Packaging

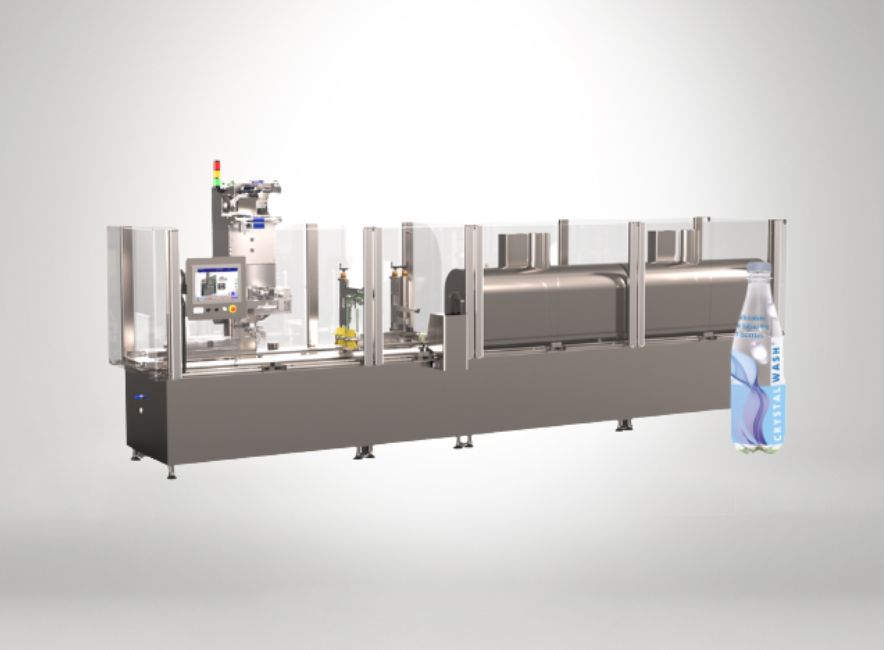

Home Specialties Combisteam Crystal Wash® FB500 – AI200

Combisteam Crystal Wash®

FB500 - AI200Accelerate your ecological transition by integrating your PET bottles into the US recycling stream

Features

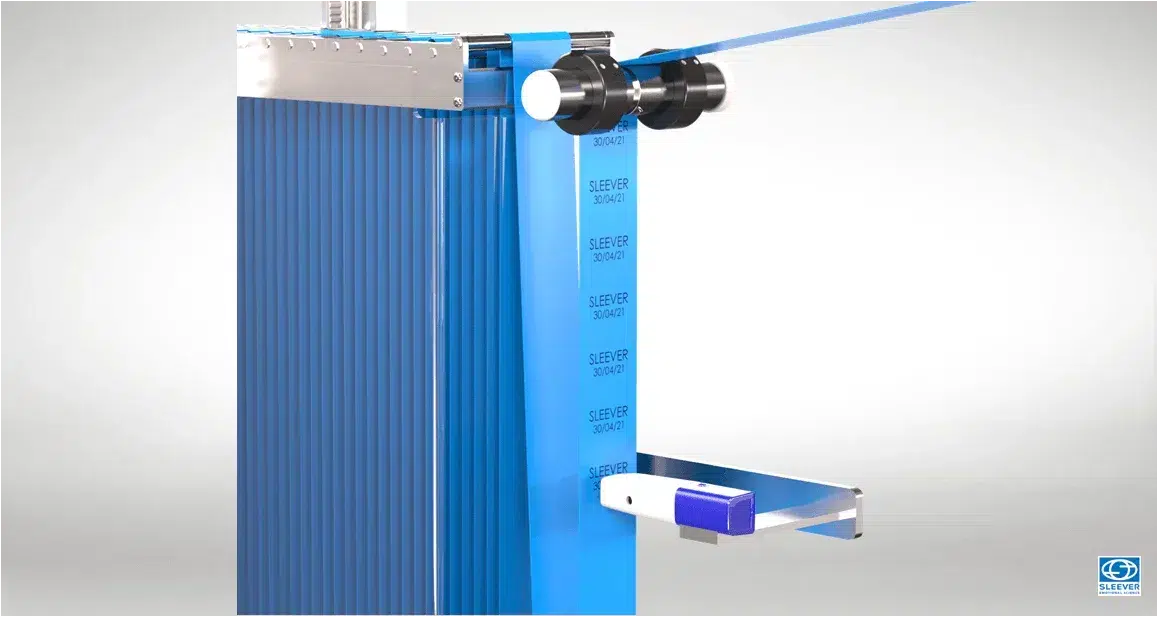

A high-capacity magazine to ensure autonomy.

An ergonomic design for easy and quick reel connections

This high-capacity unwind unit can handle high sleeving speeds and is designed to accommodate new generation films. Located outside the machine, it offers easy access to the reels, which are positioned at hand level; the splicing table allows for quick and error-free splicing. The overall system provides autonomy and ergonomics, for operator comfort.

Energy consumption tailored to each format.

Energy management to reduce the carbon footprint of your products.

This exclusive shrink technology combines several systems: the expansion chamber, the height-adjustable tunnel and the steam diffusion system are adjusted to each product to optimize energy consumption.

Innovative technology to enhance the recyclability of your PE-PP packaging

An innovative technology for the recyclability of your PET bottles

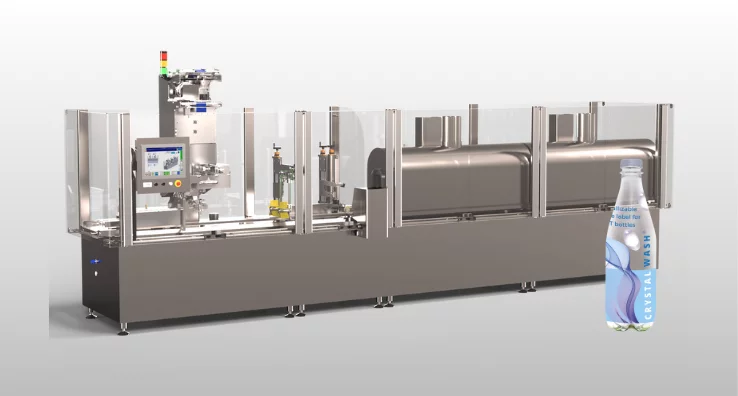

A machine designed to decorate soft drink and liquid food PET bottles of all sizes, from 100ml to 2L, even the most sophisticated shapes. This machine allows for the use of LDPET® product, a shrink-sleeve compatible with the closed-loop PET recycling process (bottle-to-bottle).

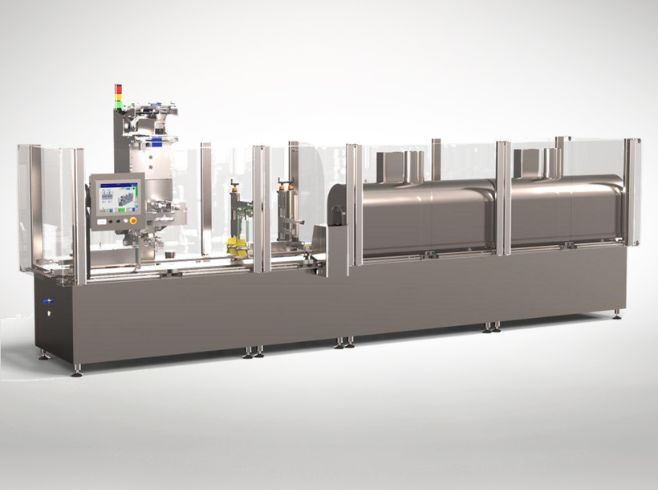

Modules designed for high speeds in the liquid food industry.

Modularity at the service of performance

To work at high speed in wet conditions, this machine is equipped with modules to guarantee the performance and quality of your products: a drying module at the inlet to facilitate shrink-sleeve application, an orientation system for complex shapes, and a control and ejection system.Options

Multi-reel shrink-sleeve unwinder unit with automatic splicing

Increase your autonomy for greater productivity

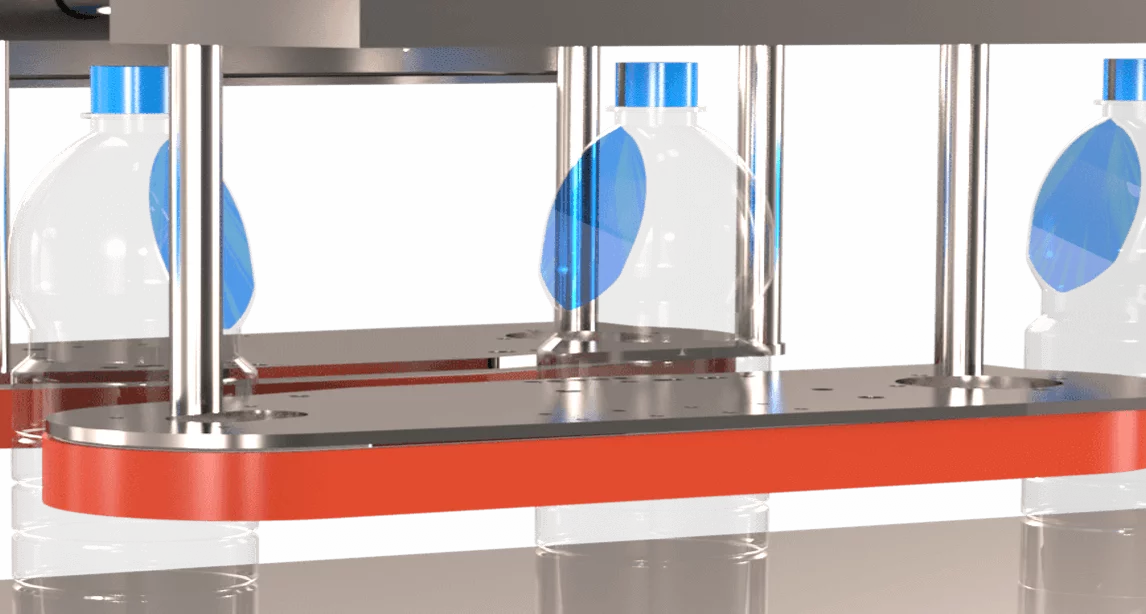

Camera vision module for detection and product orientation using belts

The assurance of a well-positioned shrink-sleeve label on shaped bottles

Drying module at the end of the shrinking tunnel

The guarantee of a dry product for the packaging at the end of the line

Coding and traceability module

Product serialization and marking to meet food standardsSpecifications

* Non contractual information

Machine

Conveyor height980 +/- 50 mmSpeed500 cpmCutting diameter100 mmSteam consumption200 Kg/hSteam pressure6 – 8 barsElectrical consumption12 kWHMachine length6400 mm

Packaging

MaterialsPETShapesCylindrical, square, complex shapes...Products diameter45 to 70 mmProduct height185 – 210 mmSizes20 ml – 1 l

Sleeves

ApplicationFull body, partial sleeveType of filmsTPEG, PETFilms thickness50 to 65 micronsMarkets & Packaging

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.Statistics

The technical storage or access that is used exclusively for statistical purposes. The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.