- Group

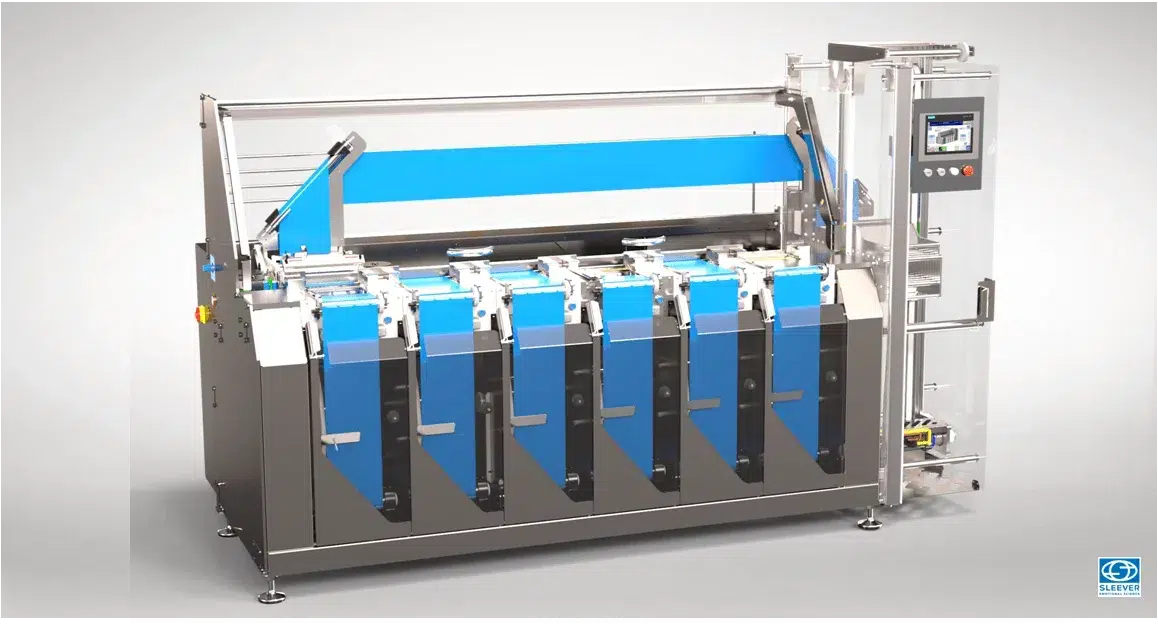

- Ultra compact machine for decoration and protection, first use guarantee and traceability of products in food, beauty, health and small household items.

- Flexibility in all its forms: multi-material, multi-form, multi-format

- Important ergonomics for operator ease of use

- A unique shrink technology that allows the use of new generation sleeves, to reduce energy consumption and facilitate the integration of packaging into circular economy flows

- Features

- Options

- Specifications

- Packaging

Home Specialties Combisteam Dreamoncup® FB600 – AI 70

Combisteam Dreamoncup®

FB600 - AI 70Unique late stage differentiation of food jars after sealing

Features

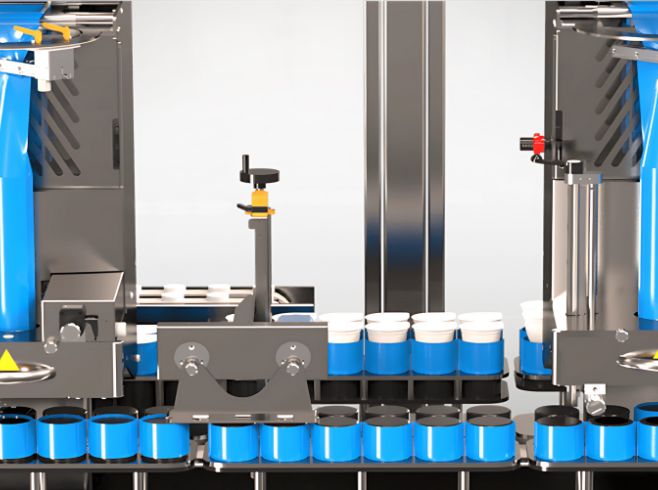

Bottom-up labelling of full jars

A technology designed for inline application after sealing

A shrink-sleeve application technology that was developed to be integrated into food jar packaging lines (sauces, dairy products, etc.), after filling and sealing, by covering them from the bottom, so as not to contaminate the lid. This allows for a differentiated unique packaging.

Application of shrink-sleeve labels on thermoformed or injected jars

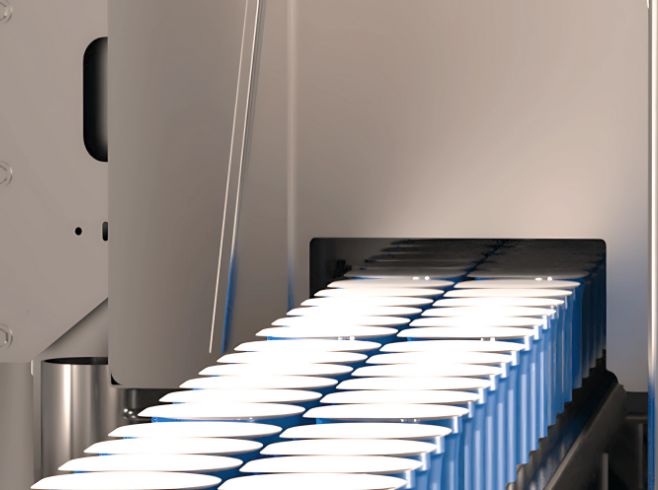

A labelling solution for medium and high production rates

An end of line design with the flexibility to process injected or thermoformed jars, either individual or in multi-packs, allowing for the late stage differentiation of food jars, regardless of their shape or configuration (from 1X2 to 2X4).

Automated loading and unloading

Automation and robots for increased performance

To improve performance, the transfer of the jars to the noria carts during the sleeving and shrinking operations are automated and performed by robots.

A technology and a shrink-sleeve designed to reduce energy consumption

A reduced carbon footprint through energy management

This machine is designed to use the latest generation of films,with optimized thickness (20 microns). The shrink tunnel can be adjusted to the height of the jars, and a steam panel allows you to adjust the consumption settings to each format.

Options

Marking and serialization module

Traceability and marking: a response to regulatory specifications

Multi-reel unwind unit

Automatic unwind unit for high speed production ratesSpecifications

* Non contractual information

Machine

Conveyor height980 +/- 50 mmSpeed200 – 600 cpmSteam consumption70 Kg/hSteam pressure6 – 8 barsElectrical consumption12 kWhMachine length8080 mm

Packaging

MaterialsPET, PS, PP …ShapesCylindrical, oval, square,...SizesFrom 60 to 800gProducts diameterFrom 70 to 98 mmProduct heightFrom 60 to 150 mmSizes100 gr – 800 gr

Sleeves

ApplicationFull bodyType of filmsPET, TPEG, PET opaqueFilms thickness20 to 40 micronsMarkets & Packaging

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.Statistics

The technical storage or access that is used exclusively for statistical purposes. The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.