- Group

- A compact machine, which can be integrated into low speed packaging lines for the food, hygiene and cleaning products.

- An operator-friendly graphic panel

- A modular and adjustable feeding system

- A unique and innovative steam shrinking tunnel design

- Features

- Options

- Specifications

- Packaging

Home Turnkey Sleeve Equipment Vertical packaging Combisteam® Combisteam® FB80 – 100

Combisteam®

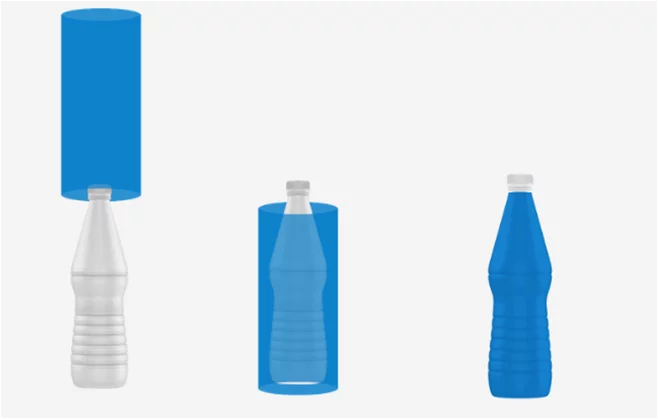

FB80 - 100The equipment for the full body decoration of complex shapes' products

Features

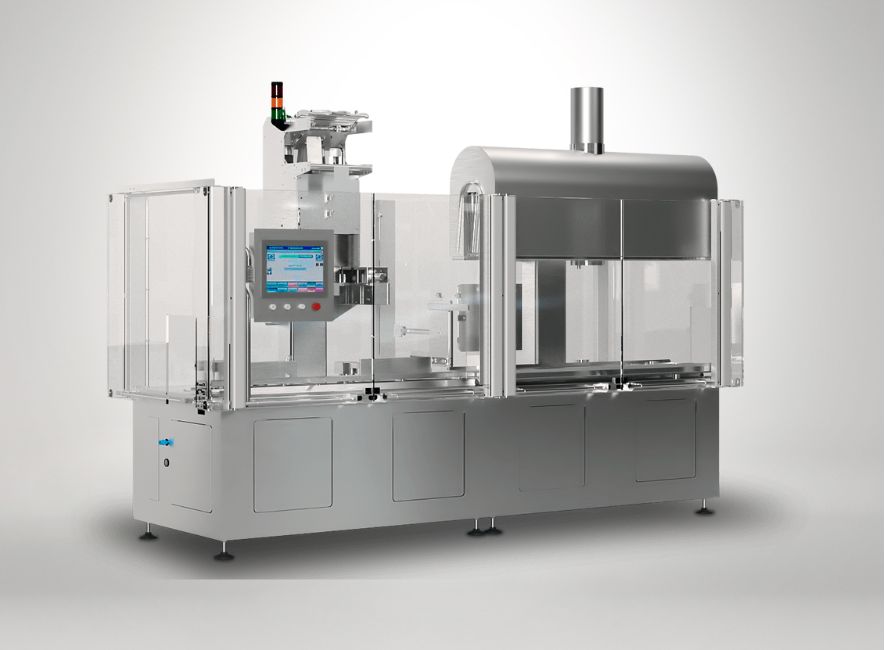

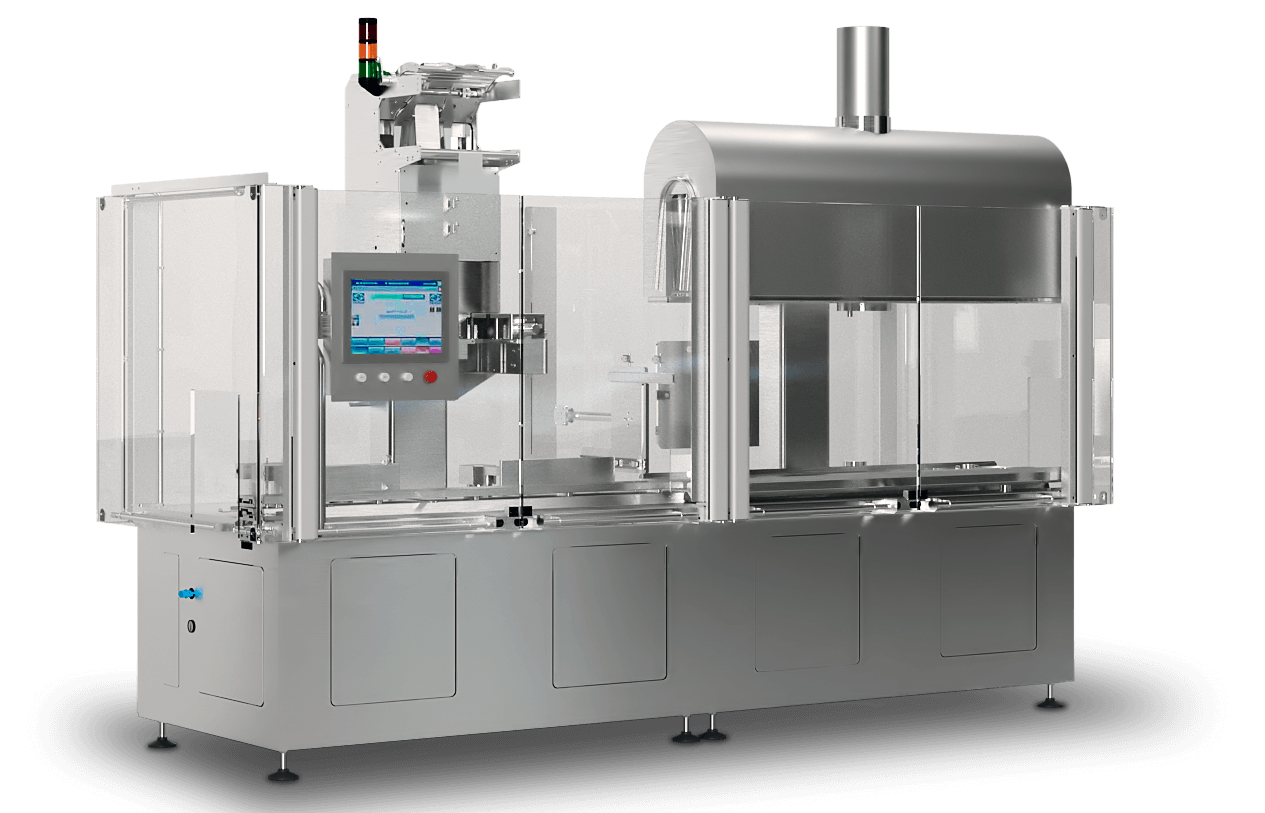

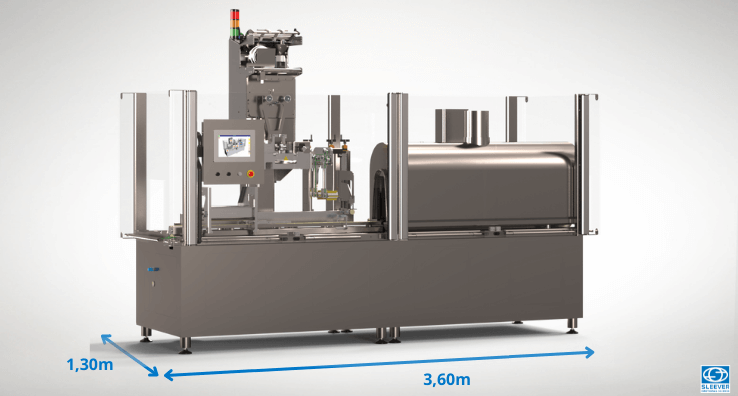

A monobloc structure for optimized floor space

An ultra-compact, all-stainless steel machine with a 360° housing

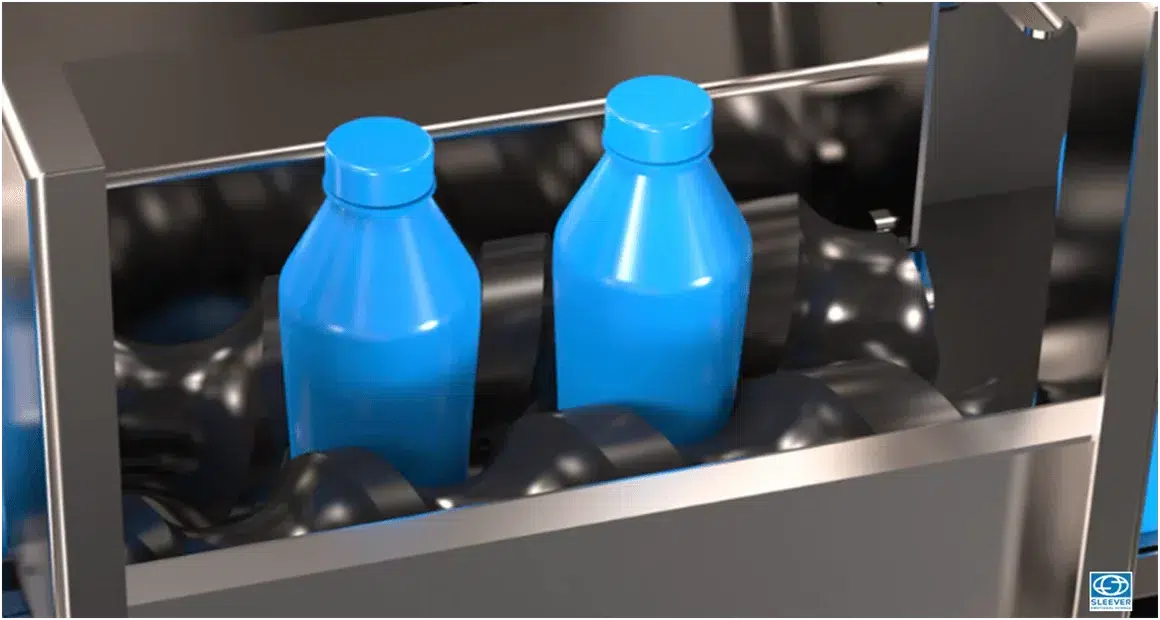

An all stainless steel monobloc structure offering an optimized footprint: it includes the applicator head, a shrink tunnel equipped with a height-adjustable system and the electrical cabinets. This machine meets the expectations of brands and subcontractors for the processing of full or empty packagings, from 50 ml to 2L, in plastic, glass or metal containers (aerosol, can, jar or bottle) to apply a shrink sleeve decoration label.

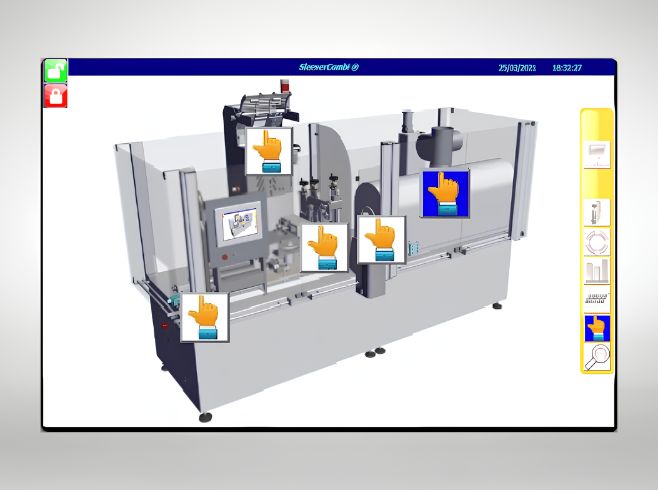

Intuitive graphical touch interface

A large touch screen that makes it easy to understand and control the machine

The operator controls all the supervision functions throughout production with a large screen featuring a user-friendly graphic interface.

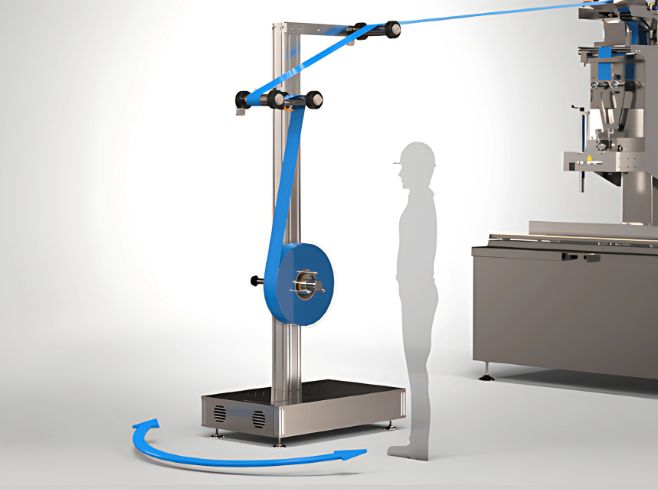

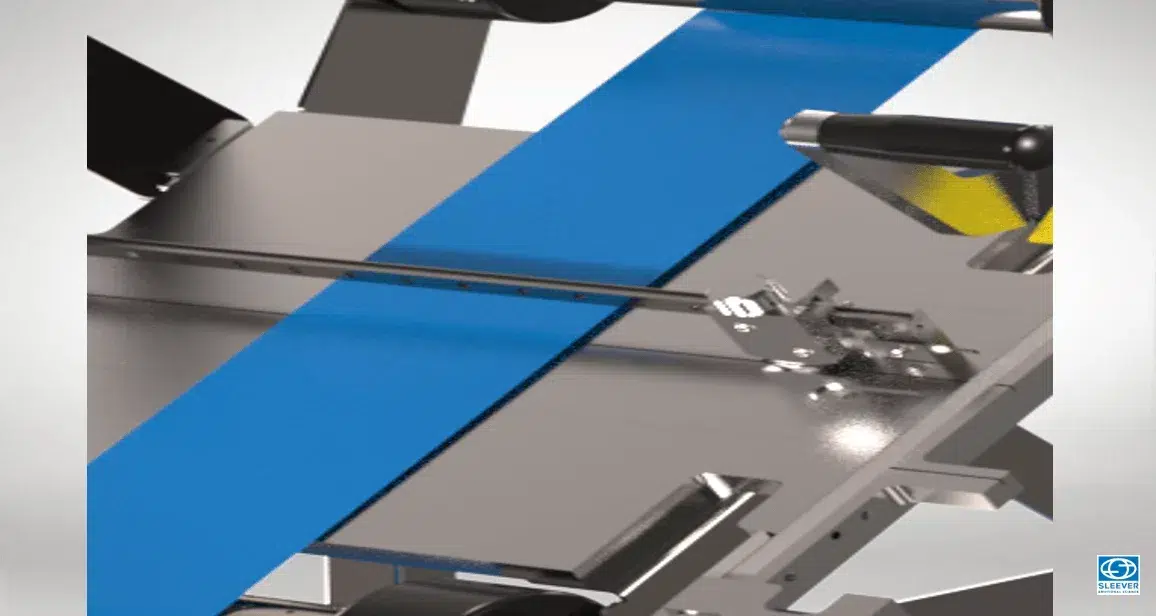

A remote, adjustable and multi-functional shrink-sleeve unwinder unit

Easy access, orientation and multiple functions to suit with your line

Operators have easy access to the loading station which is positioned at standard operator height. The shrink-sleeve unwinder unit can be fully rotated for better ergonomics and can be upgraded to integrate optional features: splicing table, multi-reels holder, coding, micro-perforation…

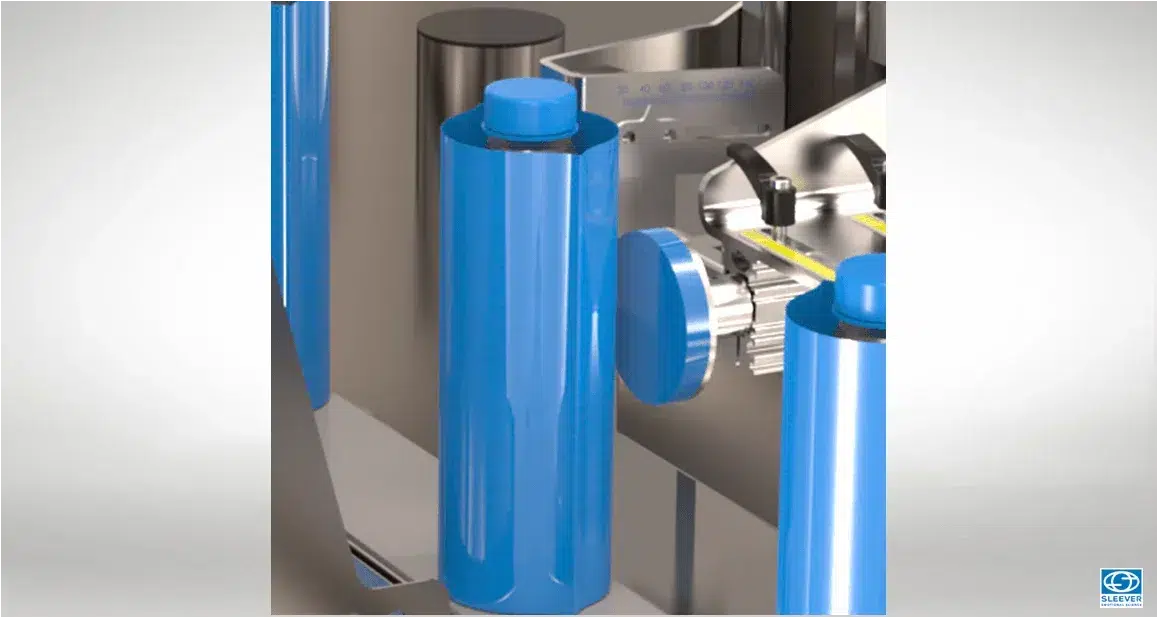

Steam shrink tunnel with controlled energy consumption

Optimize your carbon footprint, control your energy consumption

The unique and innovative design of the steam shrink tunnel minimizes energy consumption through the combination of three key elements: a height -adjustable system, a steam diffusion system and an expansion chamber, all of which are sized for each format. This allows for a controlled and repeatable quality of finish.Options

Simplicity of implementation for new formats

The modular machine for multi-formats

Splicing table

The quality of the reel splice is a key element of your productivity

Multiple checks for a product of high quality

A guaranteed and constant level of qualitySpecifications

* Non contractual information

Machine

Conveyor height980 +/- 50 mmSpeed80 – 150 bpmCutting diameter100 mm - 130 mmSteam consumptionFrom 50 to 150 kg/hSteam pressure6 – 8 barsElectrical consumption9 kW/hMachine length3600 mm

Packaging

PackagingPET, PEDHShapesCylindrical, oval, square, complex shapesSizes100 ml to 2LProducts diameter35 to 128 mmProducts height35 to 300 mm

Sleeves

CoveringFull coveringType of filmsPET, RPET,…Films thickness40 to 90 micronsFinishingNeutral, printed effects, opaque...Markets & Packaging

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.Statistics

The technical storage or access that is used exclusively for statistical purposes. The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.