- Group

- A compact and autonomous machine for inline or offline production

- Ensure the partial or total protection of products in horizontal application.

- Ergonomics and operability for multi-product use at the operator’s fingertips

- Allows end-of-line identification/customisation for serialisation, coding and traceability

- Features

- Options

- Specifications

- Packaging

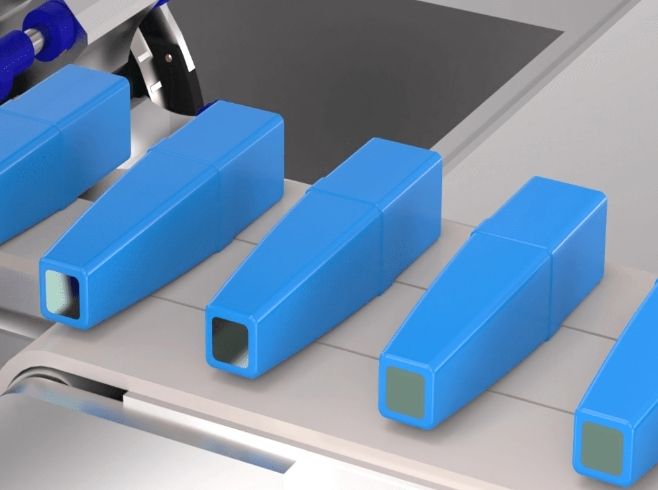

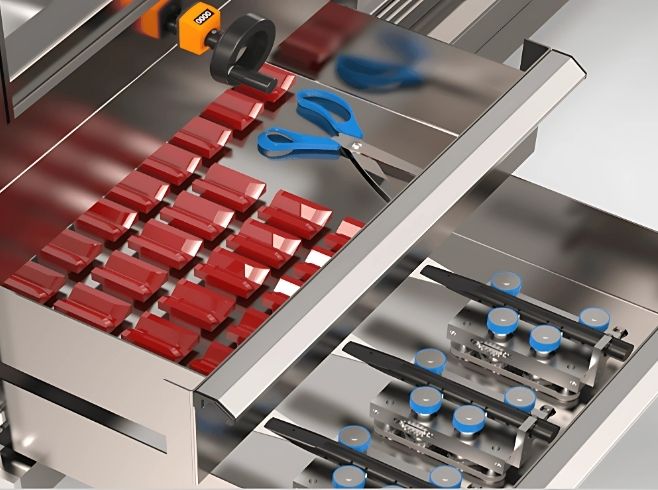

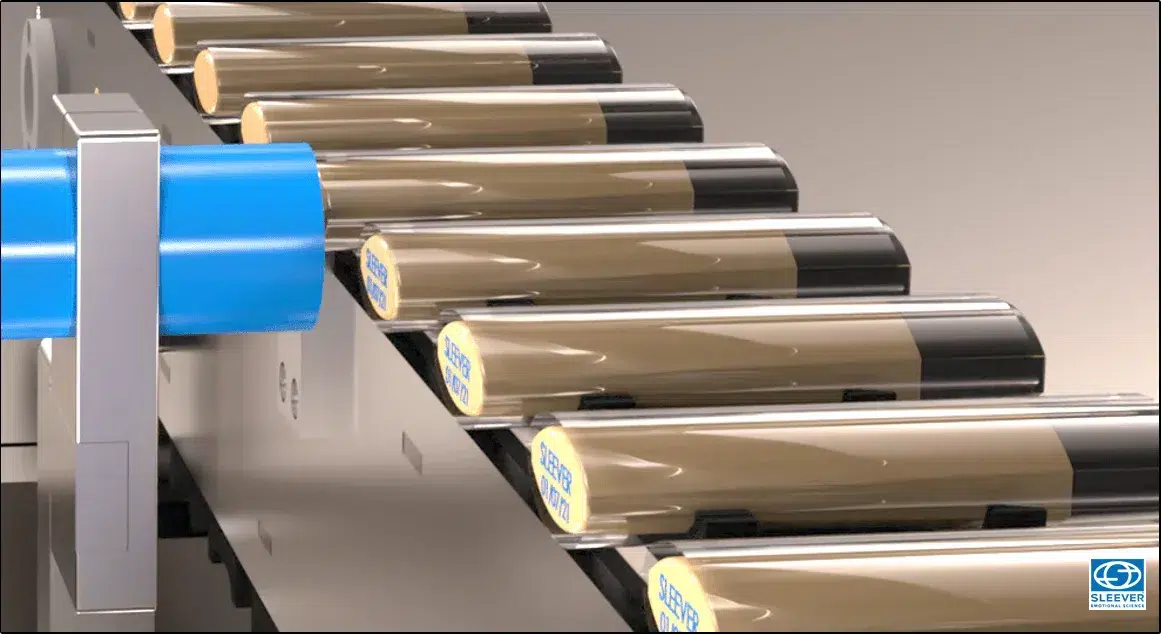

- Alternative formats can be located in the machine’s drawers for easy access and secure storage.

- Dedicated tools for each product shape allow for simple changes in a few minutes.

- Everything is in place to enable a quick and efficient restart of production, with settings stored in the menu of the HMI

Home Turnkey Sleeve Equipment Multiflexshrink® TE80 – AI15

Multiflexshrink®

TE80 - AI15Protect and secure small cosmetics, personal care and beauty products

Features

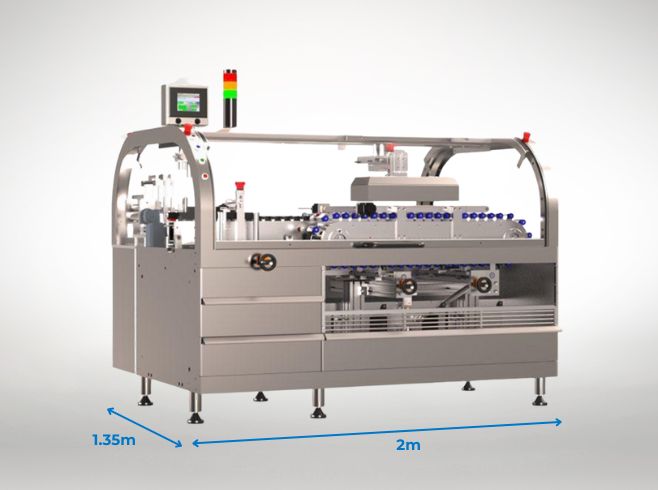

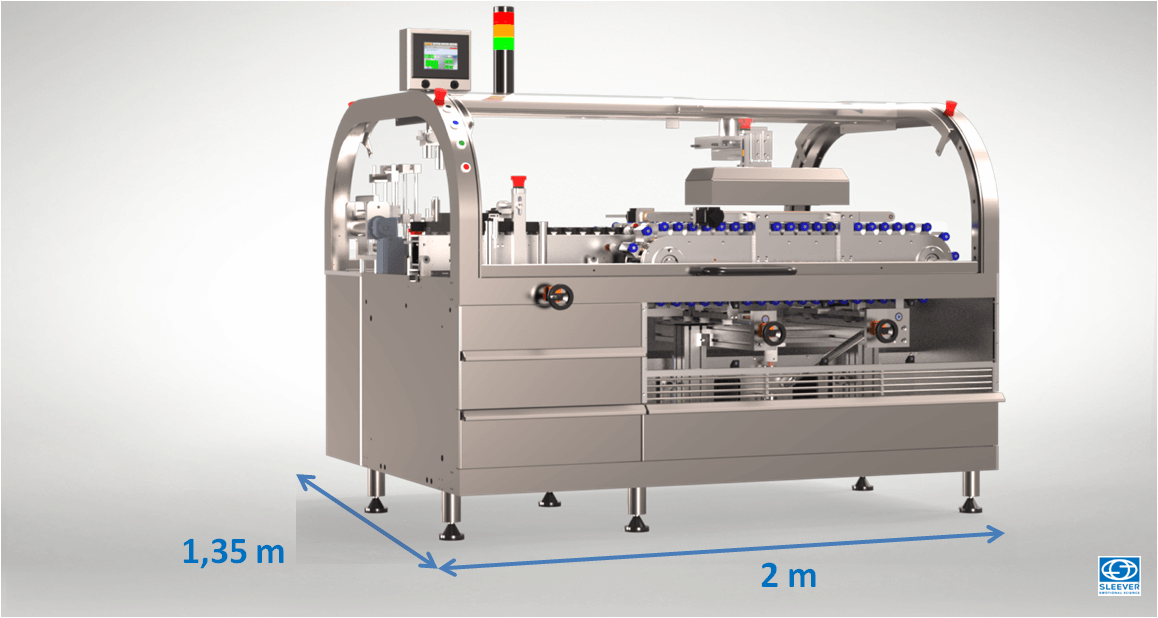

A compact machine

A machine designed for an optimized workspace

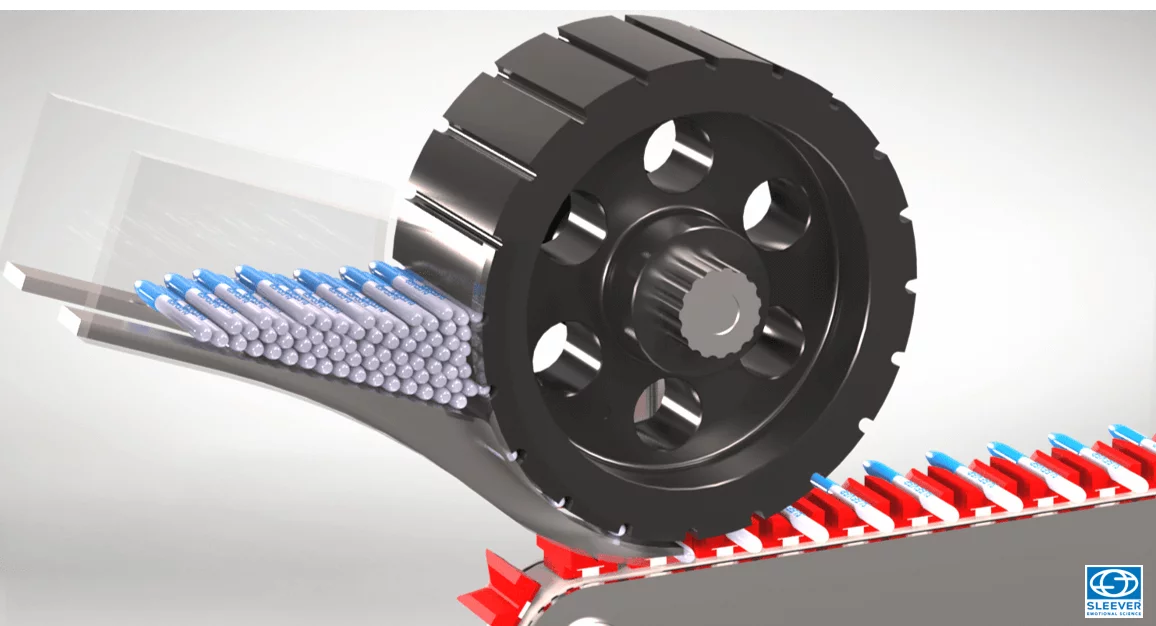

An all-in-one concept that allows for the protection, security and traceability of unstable products with sophisticated shapes using a customized horizontal application technology. Everything has been done to guarantee the quality of the finish: a rotating system avoids any contact with the conveyor belt during the shrinking phase and the infrared shrink applicator is continuously moving to avoid altering the products. This ultra-compact machine, which is designed to operate both inline and offline, meets the needs of brands and full-service companies.

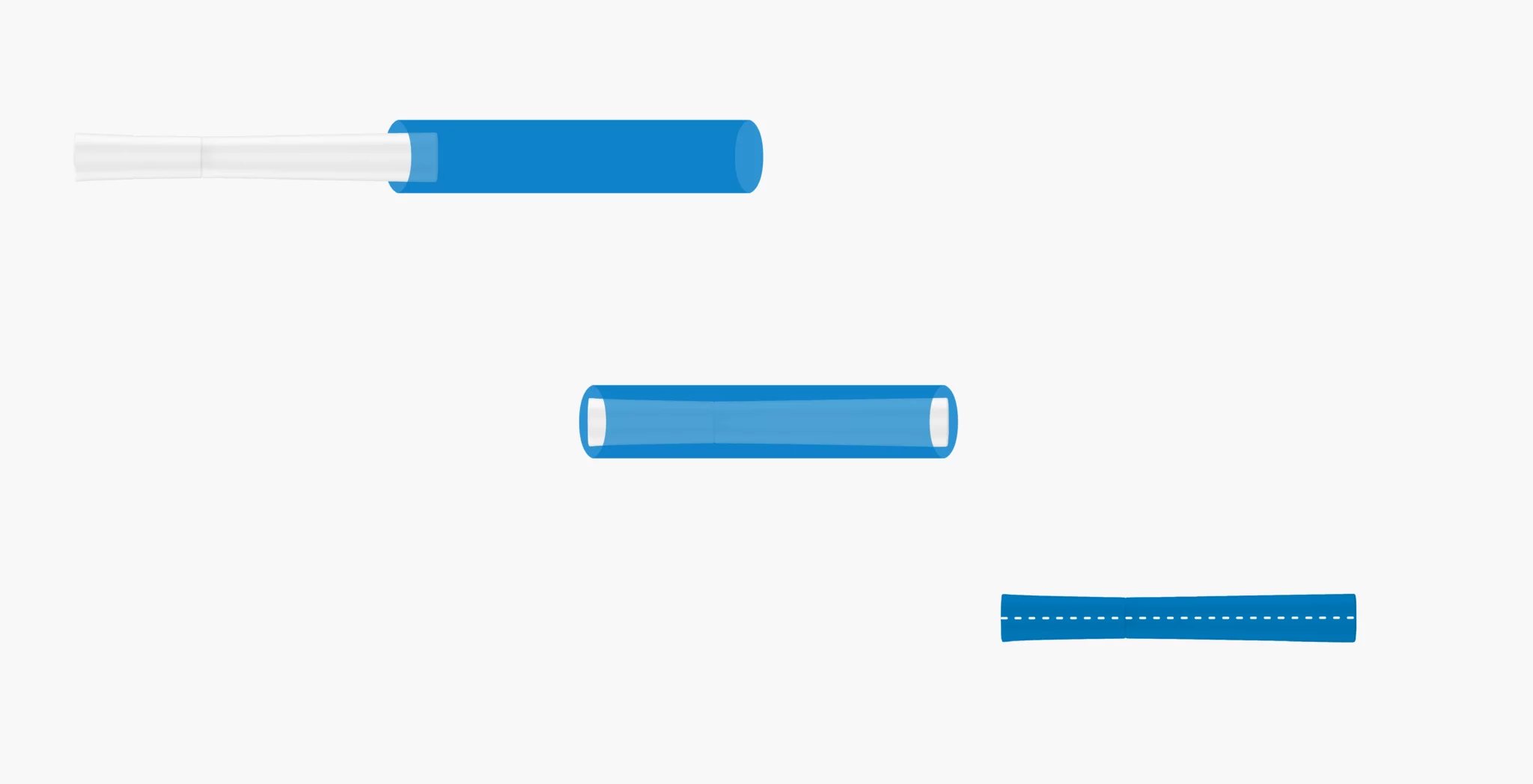

Full or partial protection

Provide protection and a tamper evident guarantee for unstable products

The evolution of market demands and the development of e-commerce require new partial or full protection features that ensure the product has not been opened before arriving with the consumer.

An ergonomic design for easy operation

Ergonomics and operator-friendly features for multi-product use

The machine has been designed to minimize downtime during format changes and increase performance.

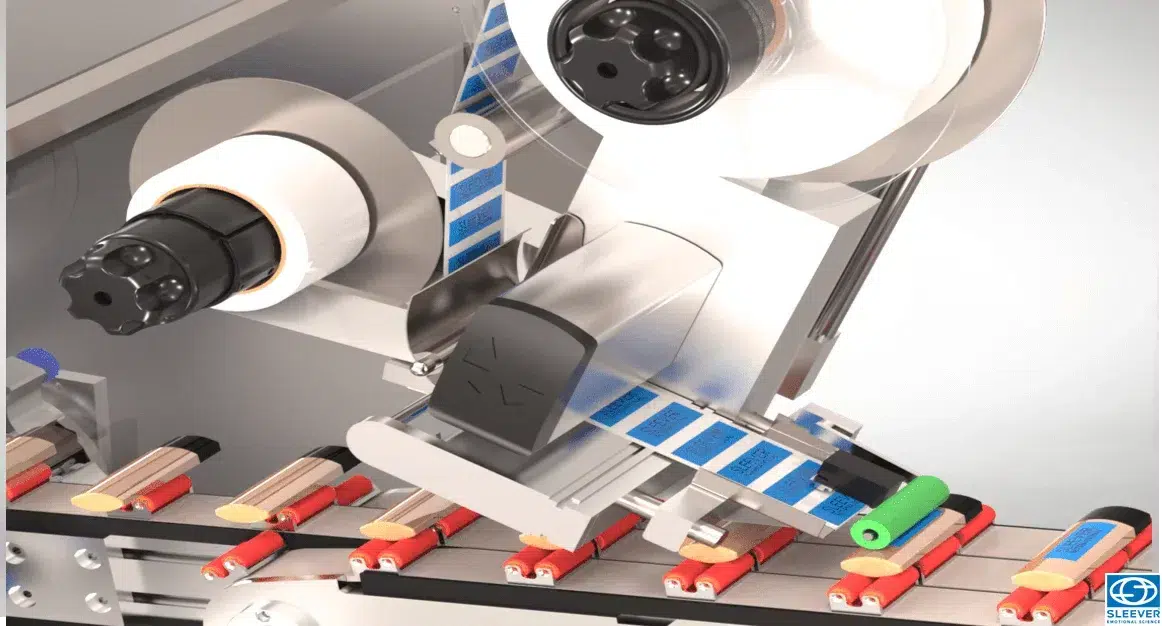

Late-stage differentiation differentiation (coding, labeling, serialization)

In-line marking technology for the ultimate customisation of your products

A technology that provides brands with the flexibility they need for late-stage differentiation such as labeling, reference coding and product serialization. All these elements allow for the desired level of finishing according to the expected level of information.Options

Single or multiple reel holder

Ergonomics and operational autonomy

Automatic product loading module

Loading module adapted to the nature of the product

Label application with orientation

Strengthen your communication

Multifunction marking module

Late stage differentiation to meet supply chain expectationsSpecifications

* Non contractual information

Machine

Conveyor height+/- 960 mmSpeed80 to 120 bpmCompressed air6 barsElectrical consumption10 to 15 kWMachine length1900 mm

Packaging

MaterialsGlass, PET, PP, MetalShapesCylindrical, square, specialSizesFrom 3 ml to 100 mLProducts diameterFrom 4 to 30 mmProducts heightFrom 65 to 150 mm

Sleeves

ApplicationProtection, security, antitheftType of filmsPET, RPET,OPSFilms thicknessFrom 30 to 60 micronsFinishingneutral, printed...Markets & Packaging

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.Statistics

The technical storage or access that is used exclusively for statistical purposes. The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.