- Group

- The solution for brand’s partners in the hygiene, personal care and parapharmacy markets

- Compact and modular equipment adapted to your production’ specifications and the use of new films with 30% rPET.

- Precise and optimal label application to guarantee the correct placement of the tamper-evident band

- A quality control system that allows you to obtain a zero defect at the end of production.

- Features

- Options

- Specifications

- Packaging

Home Turnkey Sleeve Equipment Multiflexshrink® VS TE200 – AI20

Multiflexshrink®

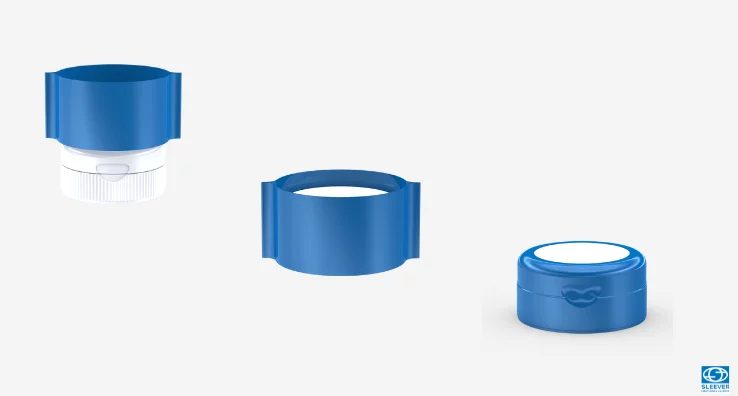

VS TE200 - AI20Flip top caps capsules: Ensuring turnkey security

Features

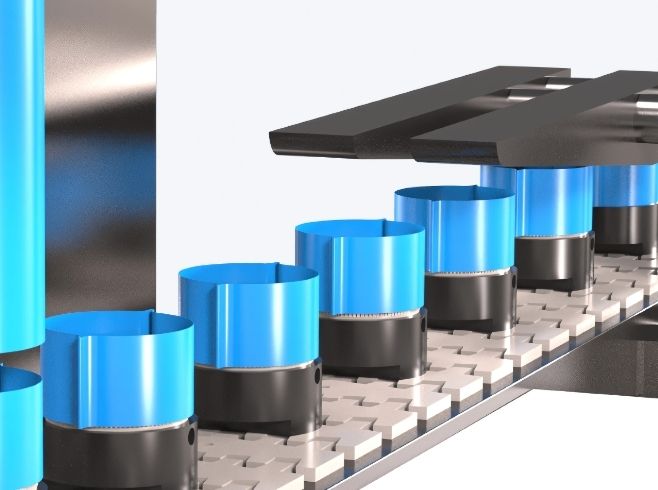

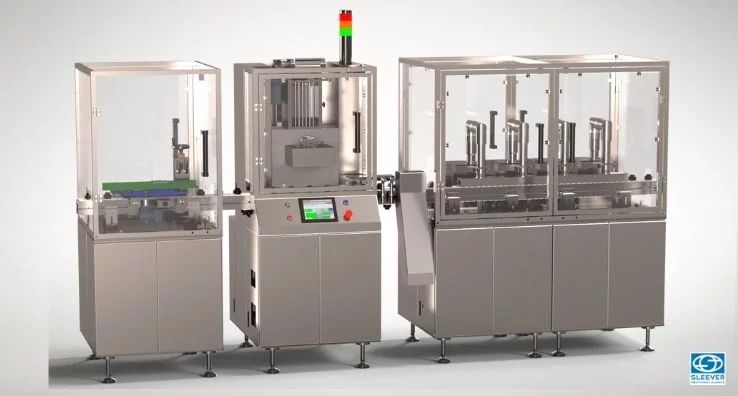

Compact and modular equipment

Modularity and flexibility at the service of security

The combination of different modules allows you to manage your range of formats and to make quick changes without requiring massive tooling. This technology allows the use of different types of films, and especially our shrink-sleeve label products with 30% r-PET to meet environmental legislations.

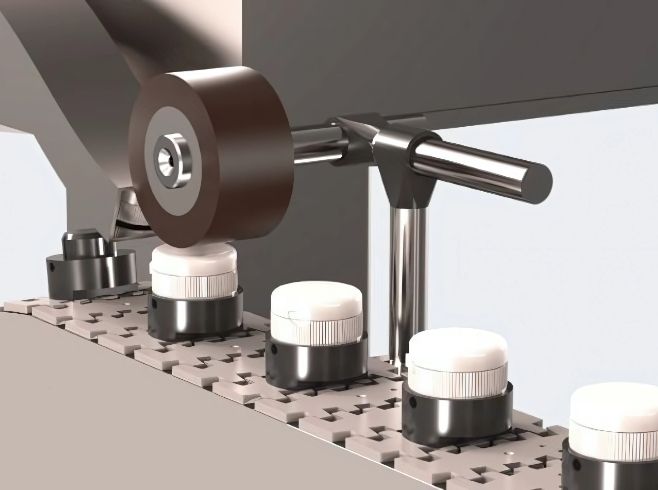

Orientation module

For a perfect orientation of the products

The orientation module always positions the flip top caps in the same direction, perpendicular to the shrink-sleeve opening system. This accurate positioning ensures that the cap is secured after shrinking.

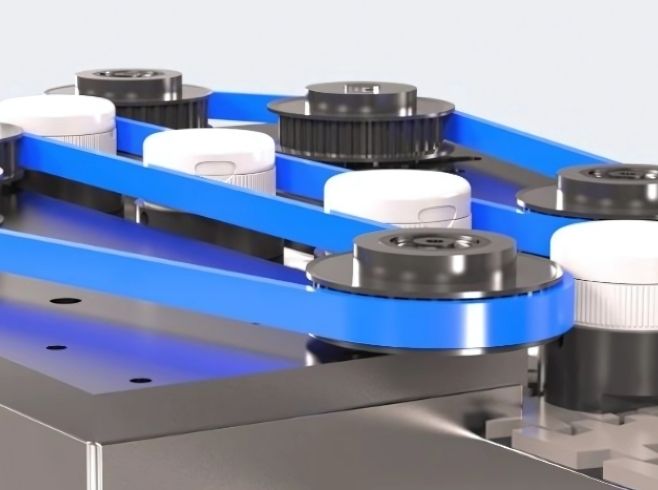

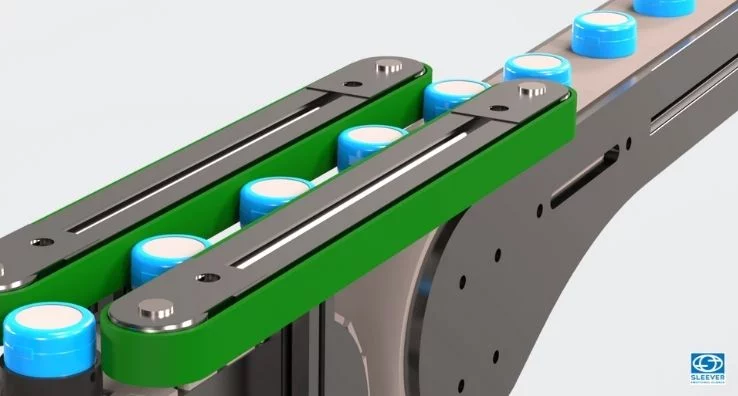

Positioning module

Precise Label positioning to ensure security

The combination of a shrink-sleeve referencing module and the design of the pad on the conveyor ensures the precise full-body (top and bottom) covering of the shrink-sleeve on the cap.

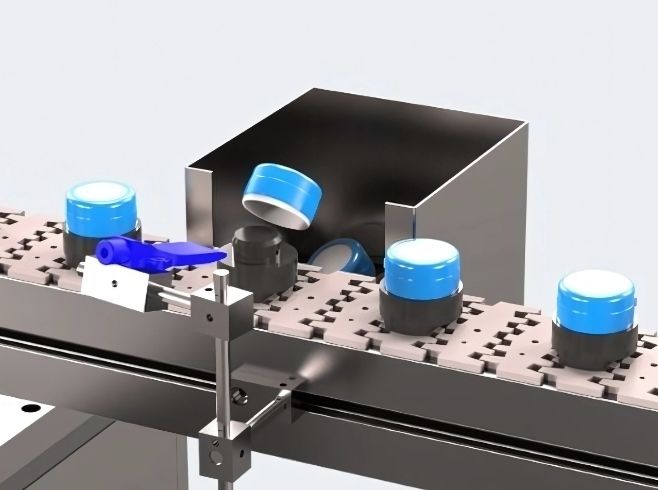

Control and ejection module

The guarantee of a secure product at the machine exit

Each stage of the production process is subject to precise control to ensure zero defects at the machine output. Thus, the placing and orientation of the cap, the placing of the shrink-sleeve label and the positioning after the sleeve’ shrinking are checked.

The solution adapted to your market specificities

The security solution that meets the specifications of flip top caps' manufacturers

A complete technical offer to guarantee the security of a flip top cap by loading, orienting the cap, fitting and shrinking a shrink-sleeve label with a micro-perforation. A solution with a high degree of autonomy to meet the speed of the packaging lines.Options

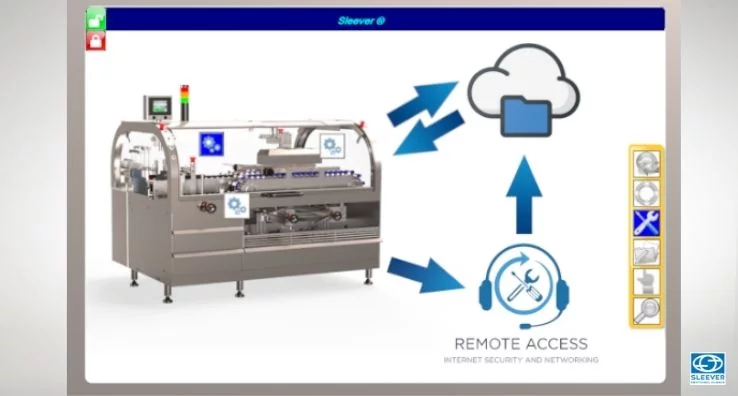

Machine connected via VPN

Interactivity at the service of performance

Transfer module at machine output

An easy transfer for your end of line operations

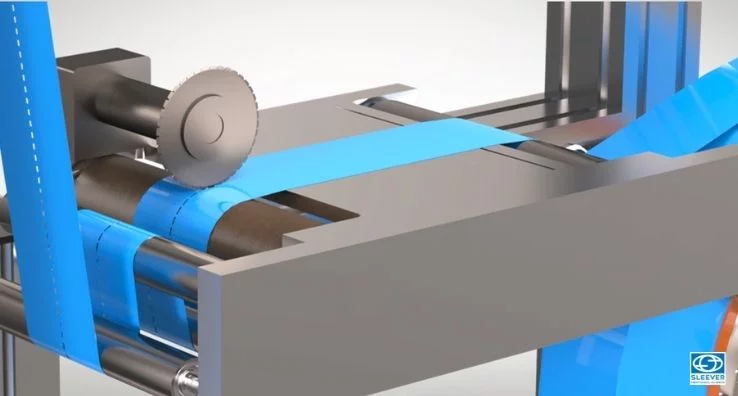

In-line micro-perforation Module

For an increased flexibility and quality assurance

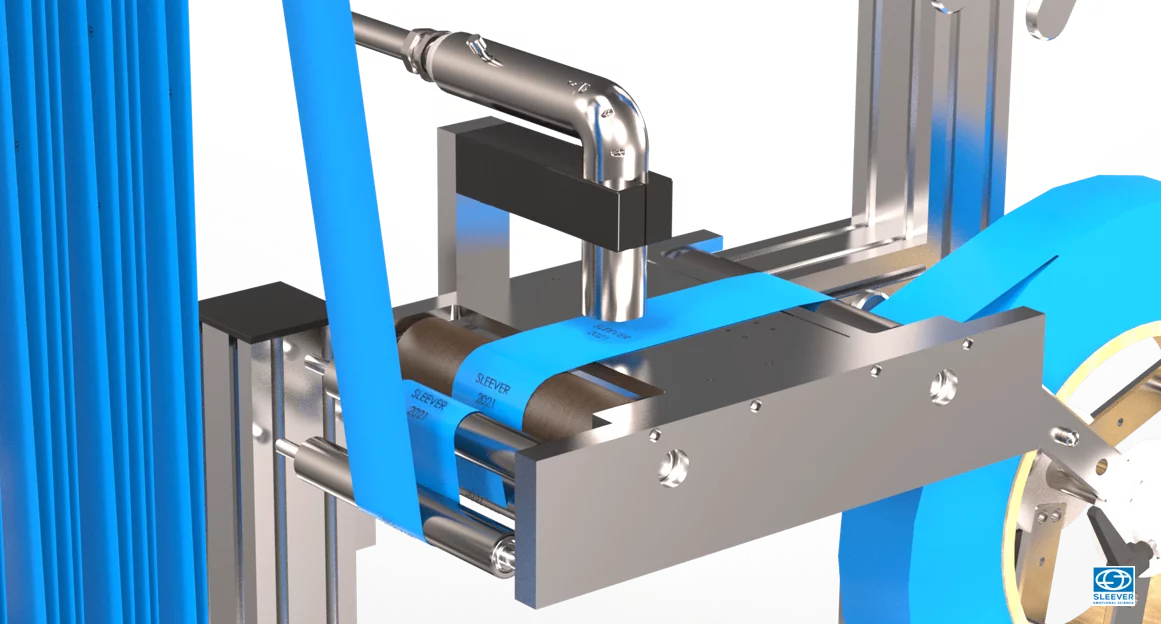

Coding module

Ensure the traceability and serialization of your productsSpecifications

* Non contractual information

Machine

Conveyor height980 mm +/- 50mmSpeed200 cpmCompressed air100 mmElectrical consumption20 kWMachine length5610 mm

Packaging

MaterialsPEHD, PPShapesCylindrical, squareProducts diameterFrom 30 to 50 mmProducts heightFrom 15 to 40 mm

Sleeves

ApplicationSecuringType of filmsPET, RPETFilms thicknessFrom 40 to 90 micronsFinishingneutral, printed...Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.Statistics

The technical storage or access that is used exclusively for statistical purposes. The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.