- Group

- Ultra compact machine for decoration and protection, guarantee of first use and traceability of products in food, beauty and health.

- Flexibility in all its forms: multi-material, multi-form, multi-format

- Well designed ergonomics for easy use by the operator

- A unique shrinking technology that allows the use of new shrink-sleeve labels, to reduce energy consumption and facilitate the integration of packaging in the circular economy.

- Features

- Options

- Specifications

- Packaging

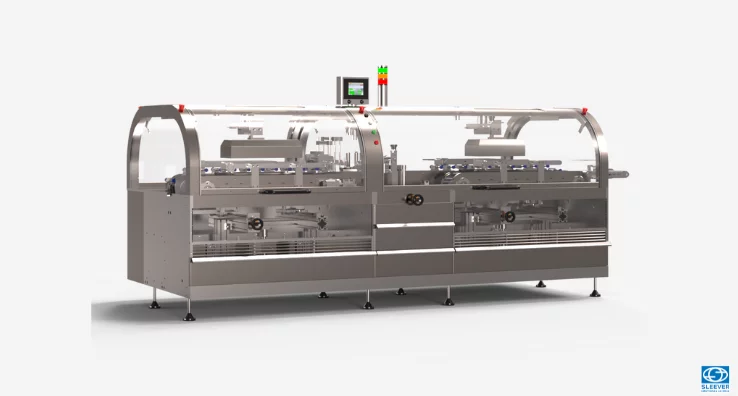

Home Turnkey Sleeve Equipment Multiflexskinner® FB-TE 80 AI 22

Multiflexskinner ®

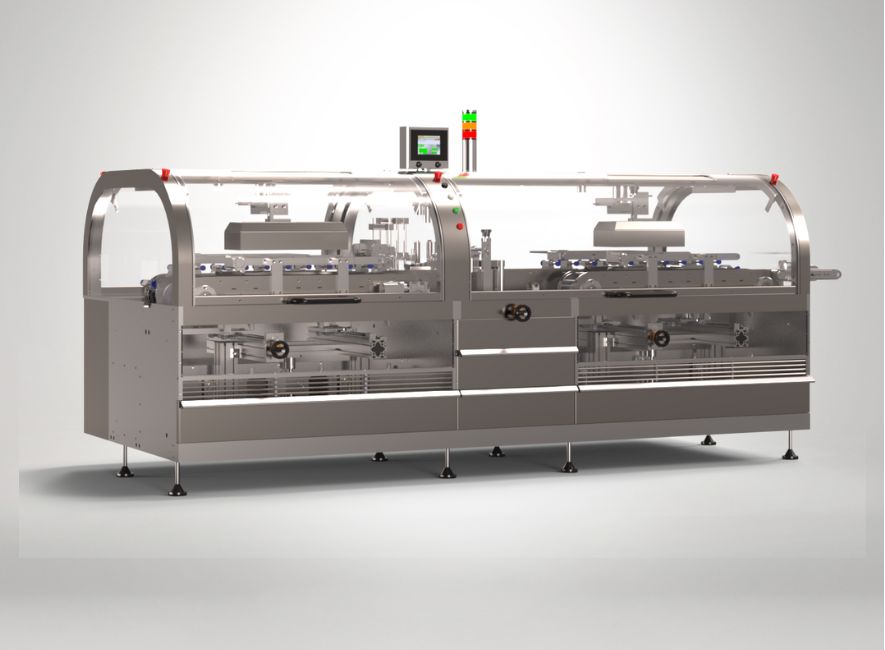

FB-TE 80 AI 22Flexible equipment for full sleeve labeling in horizontal laying

Features

Flexibility for limited series and frequent changes

A design that promotes flexibility and facilitates format changeover

Flexibility in all its aspects to manage packaging of multiple shapes, sizes, weights and materials, to easily change from a round to a square box of confectionery, from a mascara to a lipstick, from a round vial to a medical device, from a pen to a felt-tip pen or brush. Each format has its own dedicated tooling that can be changed in situ without adjustment. The conveyor carriers can hold several product shapes and are easy to change with no tooling required. The format is stored in the two drawers of the machine for easy access.

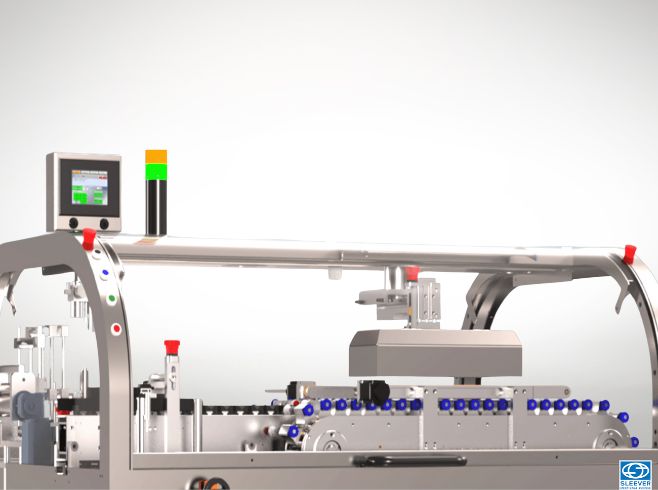

A machine designed for the operator, their safety and efficiency

Ergonomic design and intuitive interface for easy operation

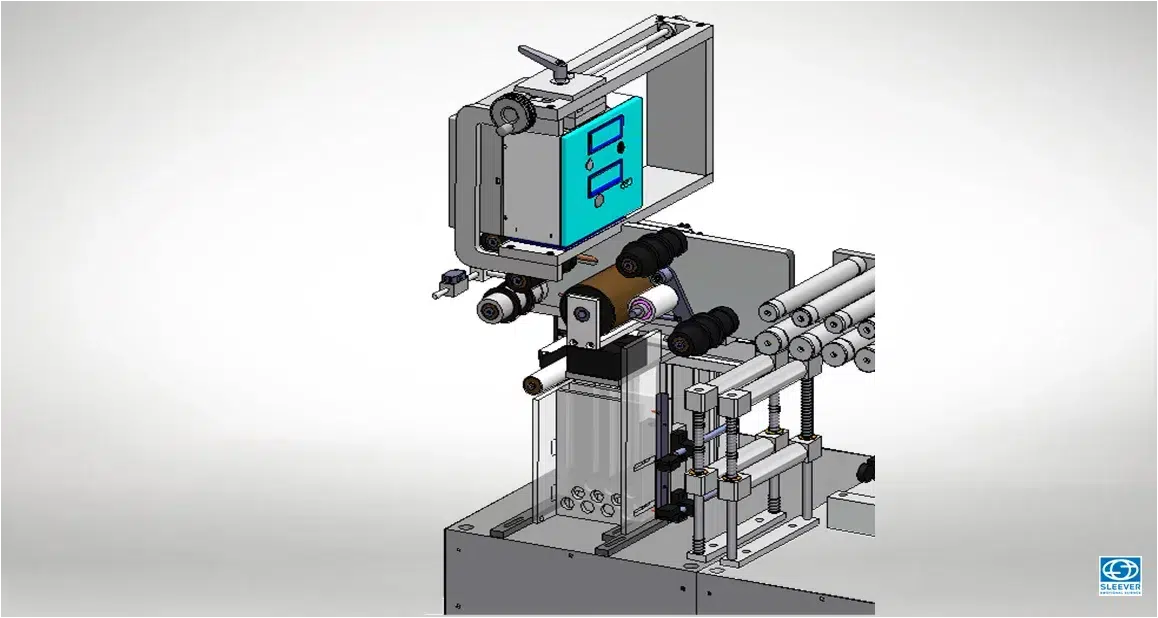

The 360° rotating HMI allows the operator to work either on the left or on the right side of the machine and can memorize up to 20 pre-set formats. On each side, a single transparent housing provides a perfect view of the interior and its wide opening gives direct access to the full production process. It is easy to change the gripping tips of the product rotation system or to control the shrink applicator.

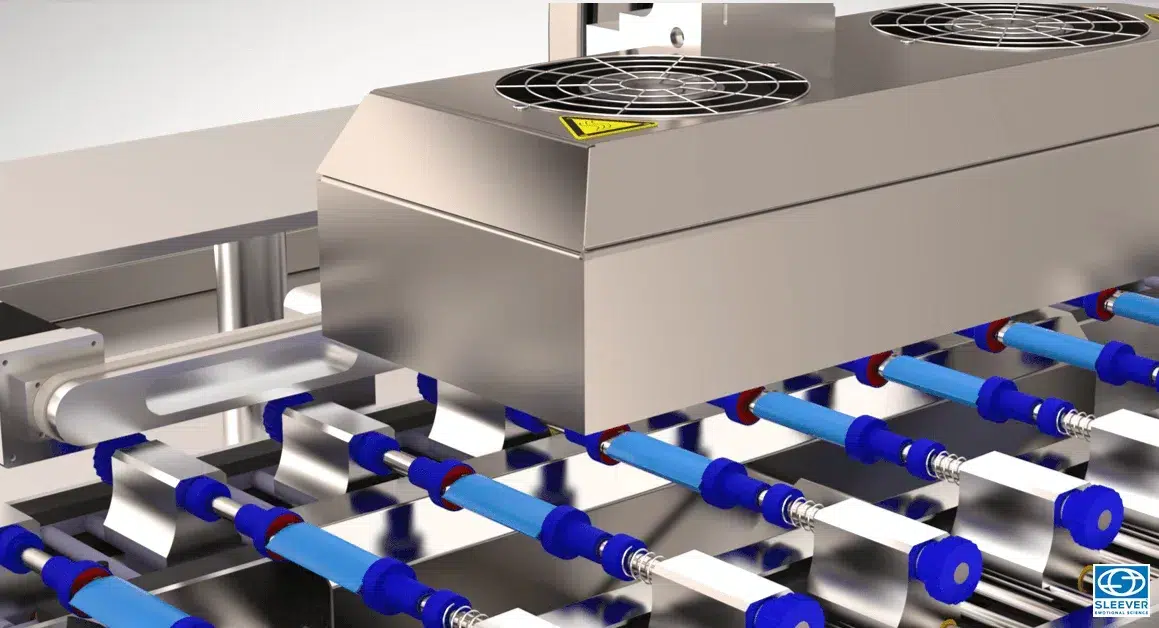

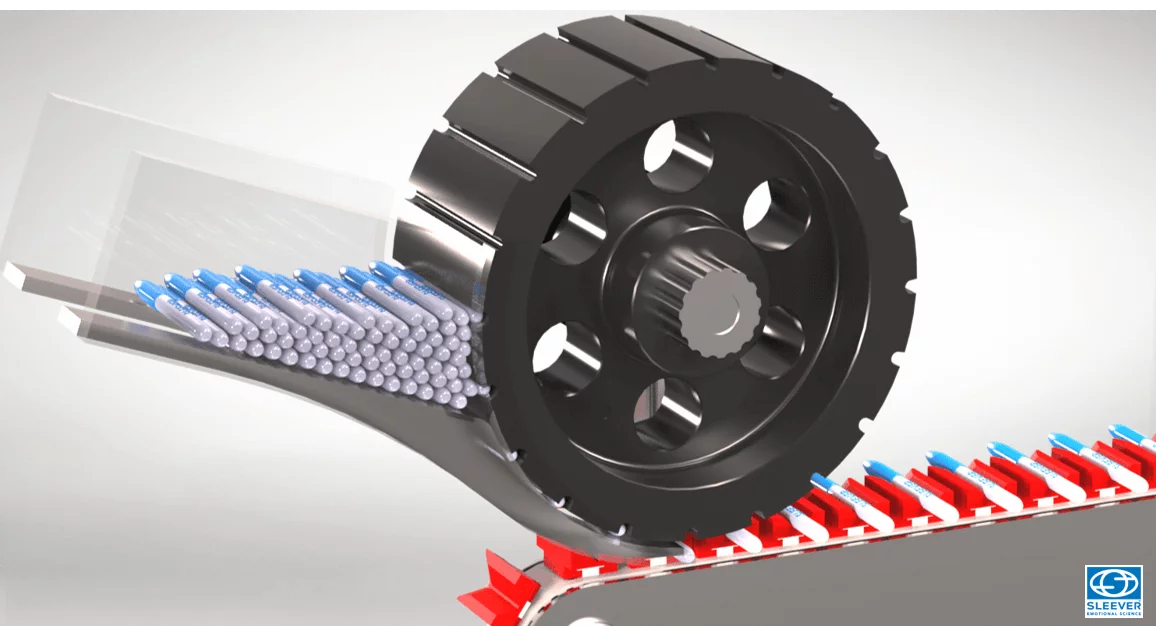

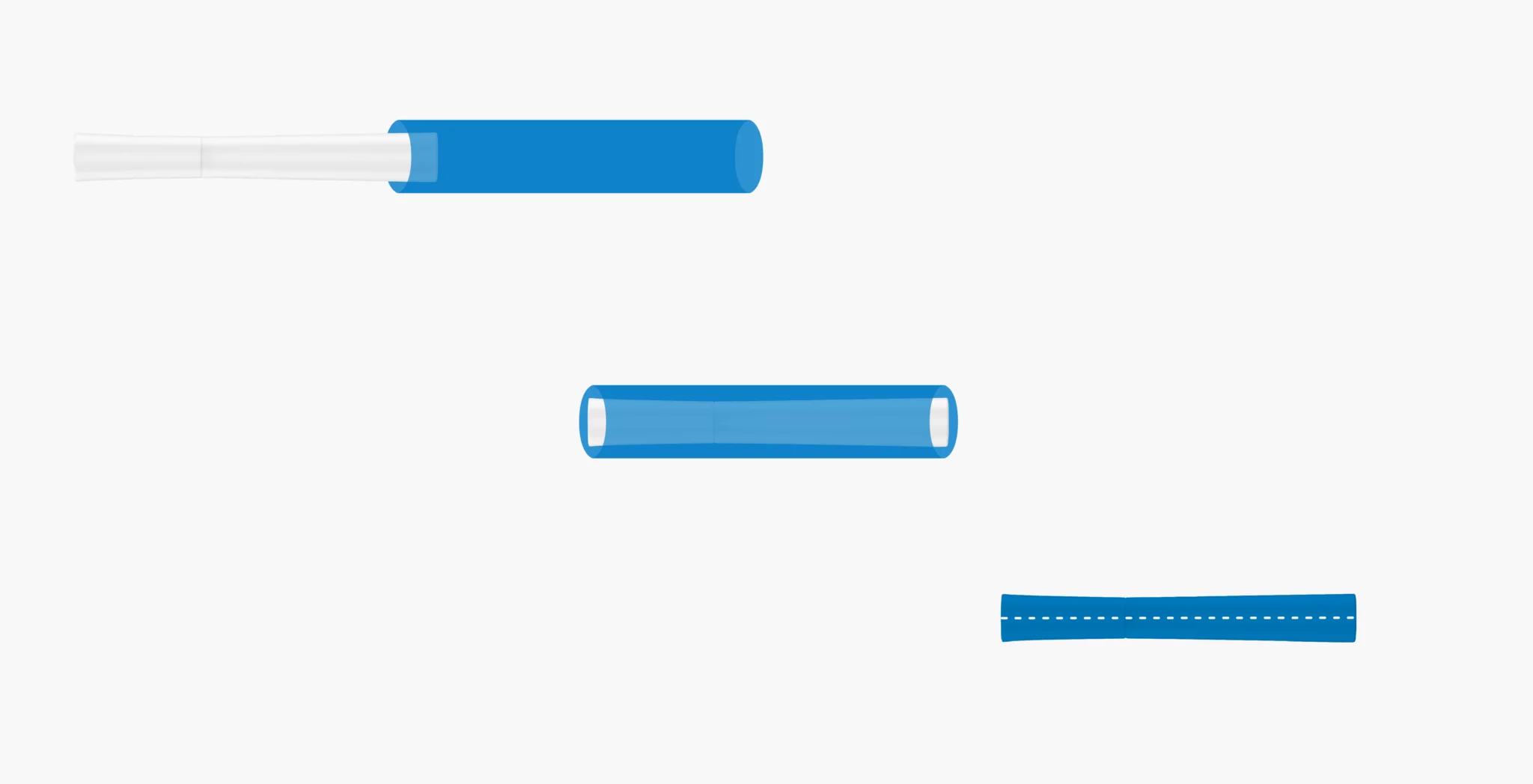

Multiflexskinner shrink technology

A unique finishing quality to enhance your products

A continuous motion rotary system prevents the products from coming into contact with the conveyor belt.There is a preheat module to prepare your product. The infrared shrink applicator and the hot air nozzle guarantee the quality of shrinkage and finishing. The product gripping tips are removable and can be adapted to different shapes (round, square, oval) to ensure a good shrink result. This technology can use shrink-sleeve of last generation to reduce the energy consumption and allow the packaging to integrate the flows of the valorized recyclability.

An ultra-compact all-in-one horizontal installation concept, in line or off line

Equipment designed for an optimized work space

An all-in-one concept that allows decoration or security and traceability for unstable products, in small sizes, with horizontal application and is equipped with an adapted preheating and infrared shrink technology and hot air nozzle. This ultra-compact equipment is designed to operate in line or off line.Options

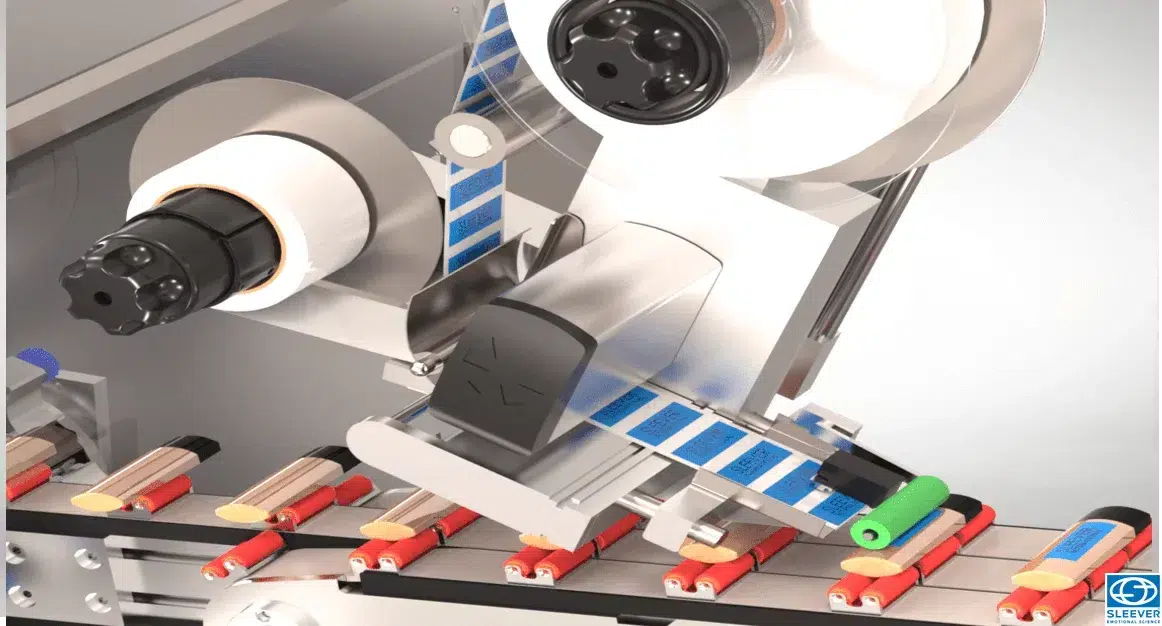

Coding systems to meet your different traceability needs

Coding module required for traceability in the supply chain

Adhesive labels for personalization

Labelling solutions for supply chain traceability

An adapted product supply in line or off line

Loading solutions for all types of products

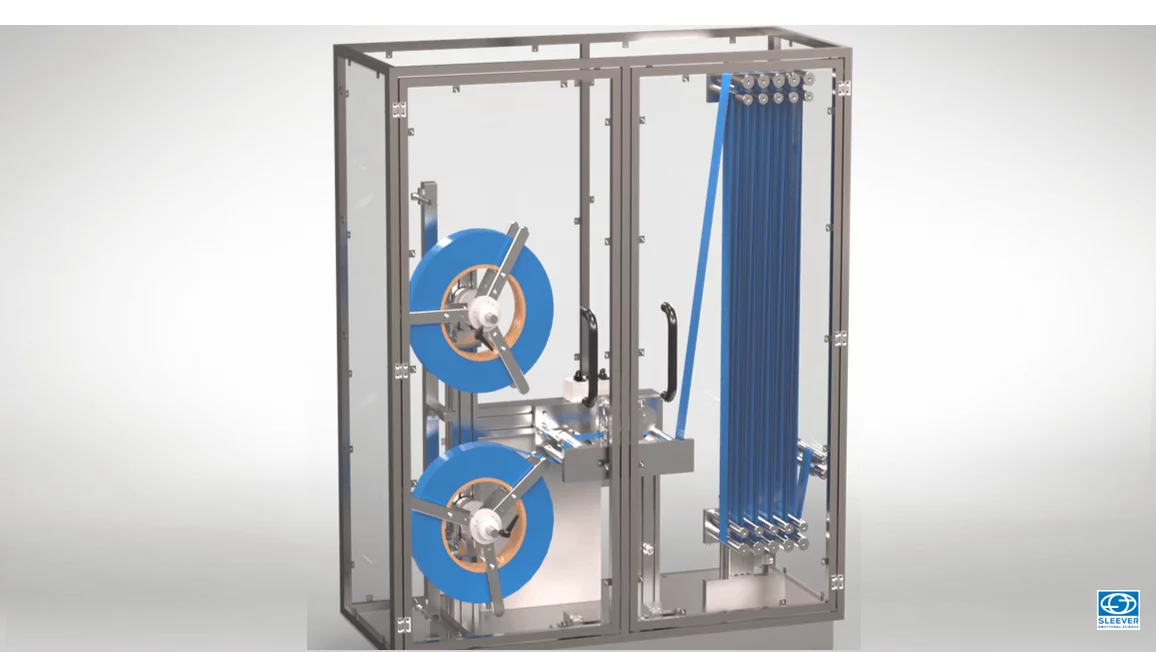

A large capacity sleeve unwinder

Bring autonomy to the operator for more flexibilitySpecifications

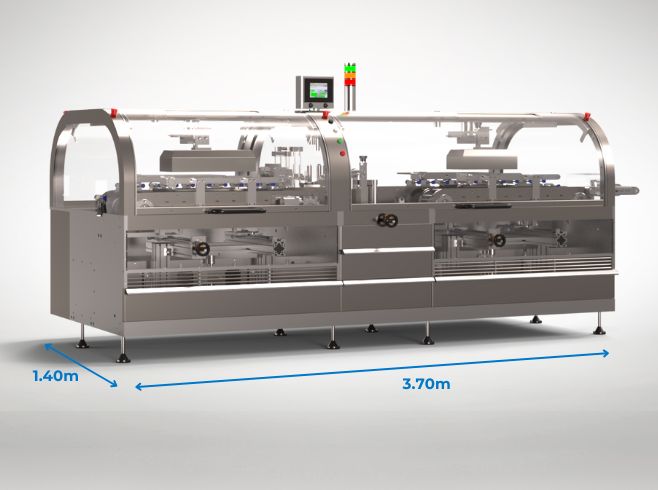

* Non contractual information

Machine

Conveyor height920 mmSpeed80 – 100 cpmCompressed air6 barsElectrical consumption7 to 22 kW / hMachine length3700 mm

Packaging

ShapesCylindrical, oval, square, specialProduct diameter4 – 50 mmProduct lenght65 – 150 mmMaterialsGlass, PET, HDPE, PP, Metal

Sleeves

Applicationfull body, partial sleeve, tamper evidenceType of filmPET, RPET, TPEGFilm thickness20 to 75 micronsMarkets and Packaging

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.Statistics

The technical storage or access that is used exclusively for statistical purposes. The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.