- Group

- Suitable for sleeving products on aseptic filling lines in humid conditions

- Frame designed for frequent and aggressive sanitation

- Delivers the desired quality and the expected performance at high speed

- The required autonomy combined with fast format changeover

- Features

- Options

- Specifications

- Packaging

Home Turnkey Sleeve Equipment Combisteam® FB400 – AI200

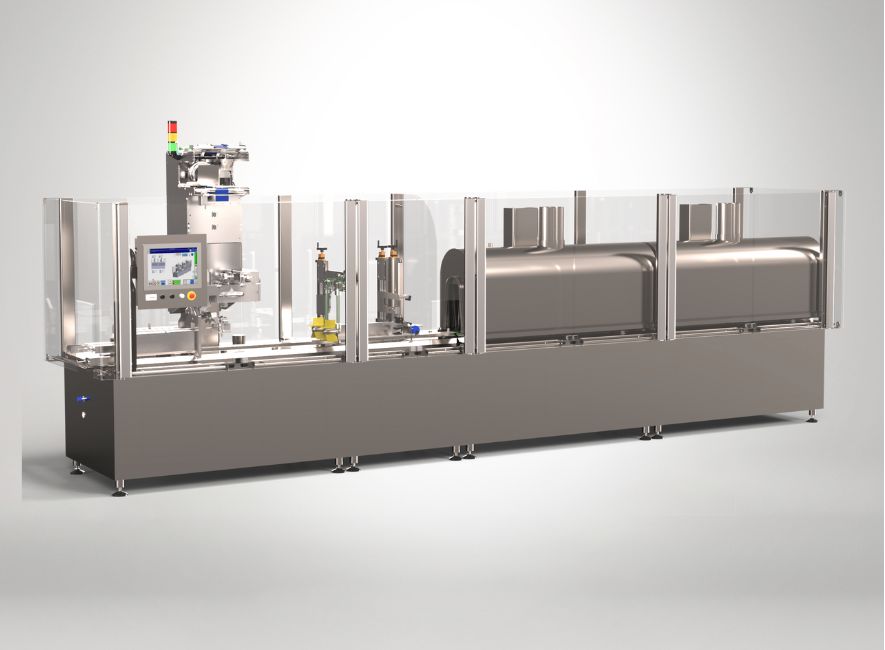

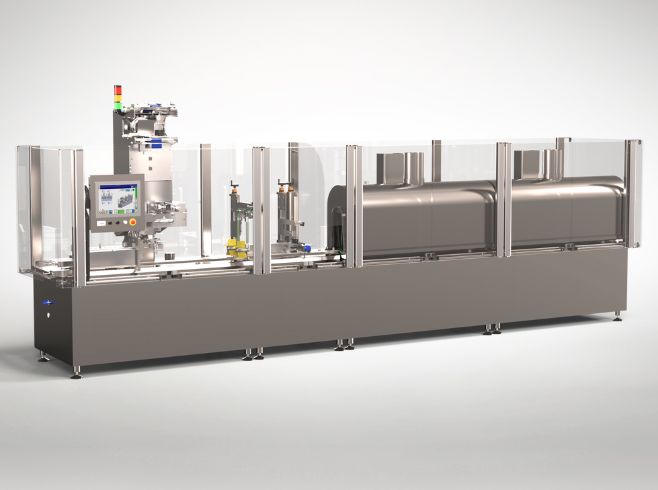

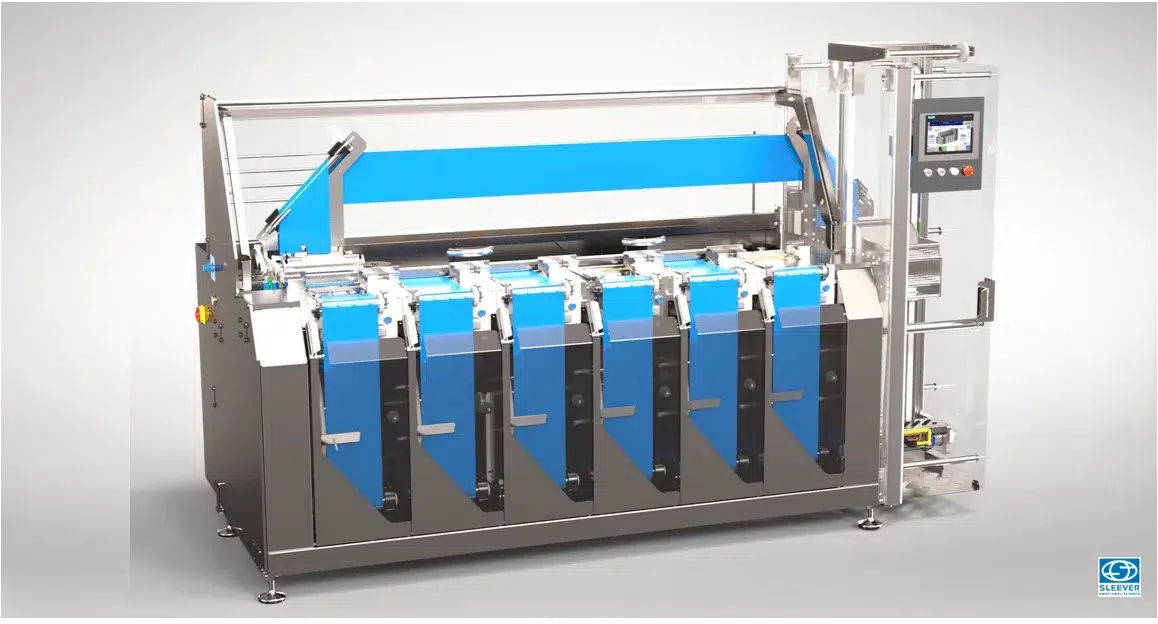

Combisteam®

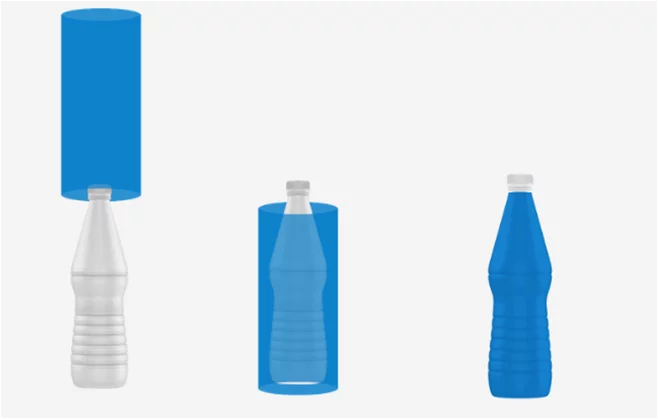

FB400 - AI200Aseptic food products' labelling in a wet environment at high speed

Features

Aseptic filling combined with an efficient labelling solution

Designed for wet working conditions

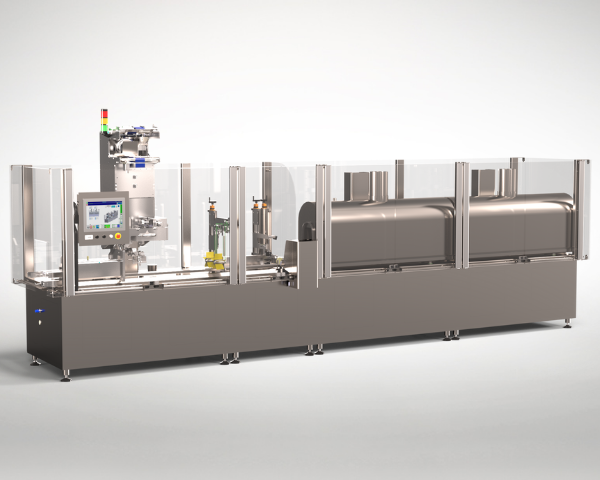

A watertight structure with a stainless steel frame to withstand humid working conditions, the equipment can be combined with dryers at the entrance and exit of the line to minimize the presence of traces of moisture on the products to be sleeved. This means taking into account the large temperature differences between the filling and sleeving phases.

Housing for easy access and use during frequent cleaning operations

A machine adapted to fresh products that require a high level of sanitation

This robust machine, which complies with manufacturing standards and sanitary regulations for fresh products, is suitable for frequent and aggressive cleaning. The machine is characterized by total transparency thanks to large doors that give access to all the accessible surfaces: the scrolling plane without any retention zone, frame, applicator head and shrink tunnel. The lifting and lowering system provides full access to ensure complete sanitation of the entire machine.

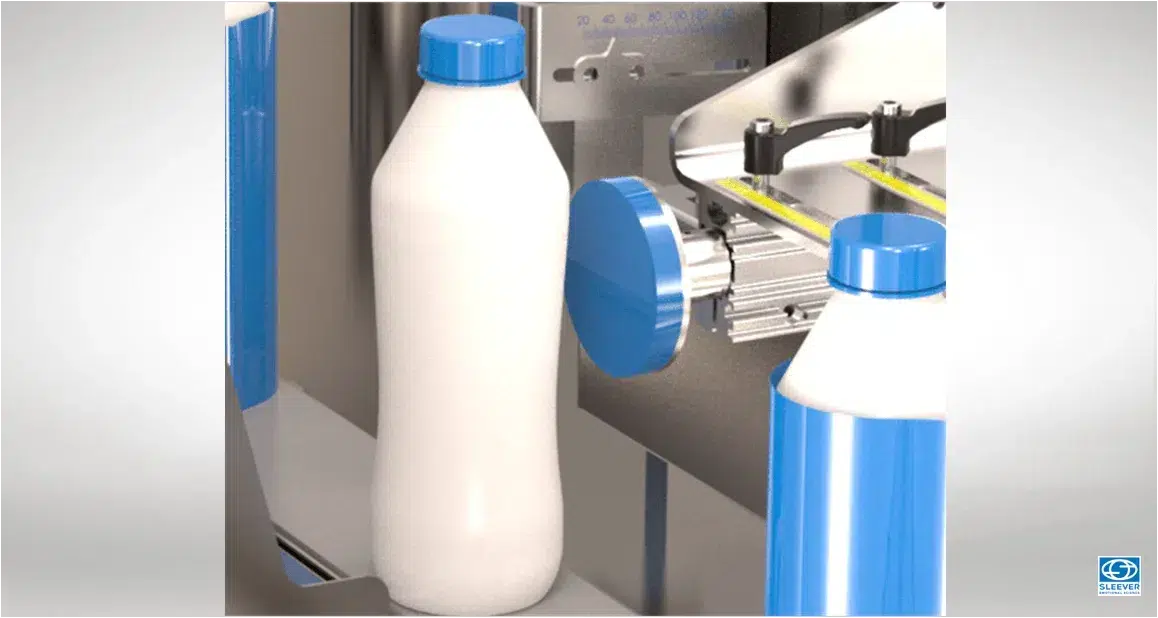

A quality control tool for high production rates and multiple formats

The performance of your line combined with an efficient control module

A machine designed for high outputs of up to 24,000 bottles per hour, for PET or HDPE containers, equipped with a quality control system that detects specified defects that may occur during production. The non-conforming products are scanned, controlled and rejected via different systems (chute, ejection table or exit conveyor), according to specifications. This ensures performance and guarantees the expected level of quality.

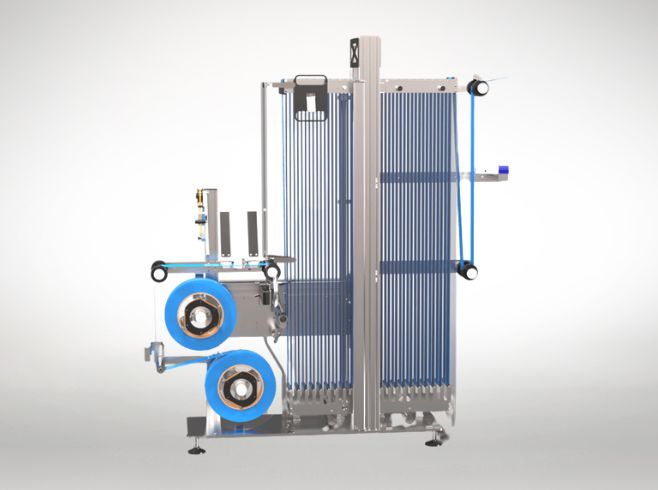

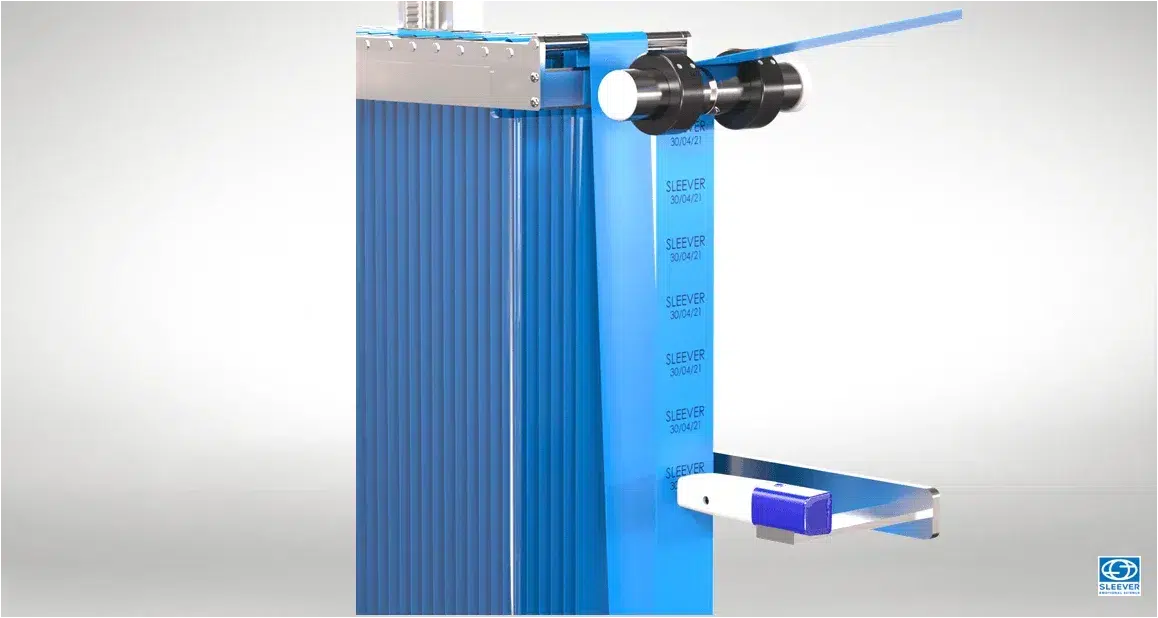

A feed system with a large capacity unwinder unit

A large capacity sleeve unwinder unit for controled reel changes

The large-capacity sleeve unwinder unit, combined with a double reel holder, which can be rotated in relation to the machine axis, is fully enclosed, easy to access and has a large capacity. It offers the operator sufficient autonomy and comfort of use to work at high speed.

Options

The Combireel multi-reel sleeve unwind unit increases your autonomy

Operator comfort remains the priority for high-speed lines

Marking and serialization module

When traceability and unit marking are required in the dairy markets

Tool trolley for your multiple formats

Reduce your format changeover times with the tool trolleySpecifications

* Non contractual information

Machine

Conveyor height980 +/- 50 mmSpeed400 bpmCutting diameter100 mmSteam consumption70 to 300 Kg/hSteam pressure6 – 8 barsElectrical consumption12 kWHMachine length6400 mm

Packaging

MaterialsPET, HDEPShapesCylindrical, oval, square, complex shapesSizes100 ml to 2LProducts diameterFrom 35 to 80 mmProducts height90 to 300 mm

Sleeves

CoveringFull coveringType of filmsPET, RPET,…Films thicknessFrom 40 to 50 micronsFinishingNeutral, printed effectsMarkets & Packaging

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.Statistics

The technical storage or access that is used exclusively for statistical purposes. The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.