- Group

- A system offer: with eco-designed sleeves for recycling HDPE/PET pots and bottles

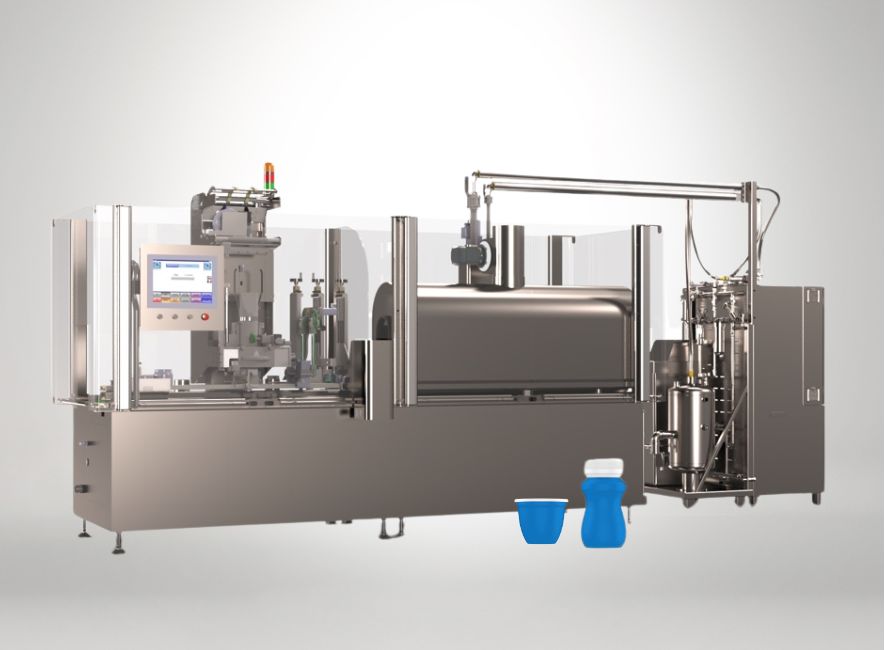

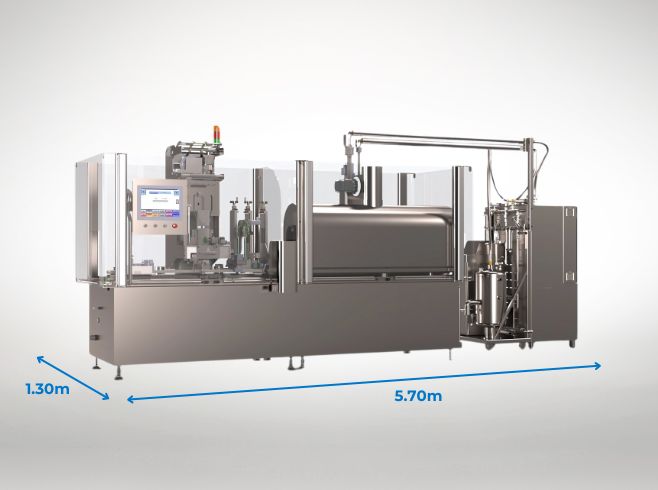

- An all-in-one modular equipment with optimized footprint and integrated steam generator

- An integrated steam generator with its water treatment to optimize energy consumption

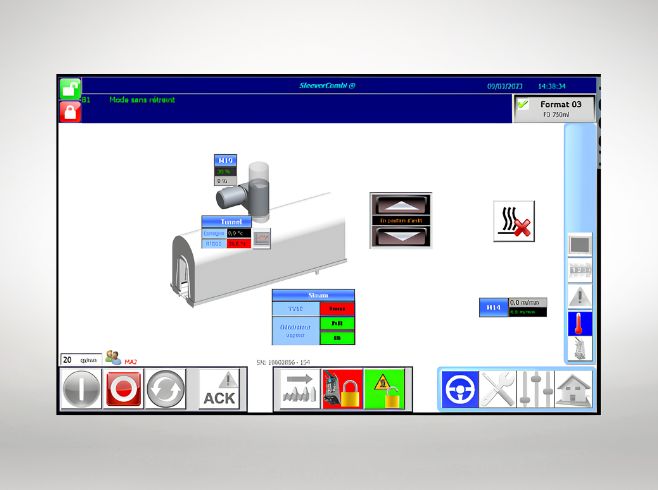

- A multi-format design, fully configurable with HMI to ensure changes

- Features

- Options

- Specifications

- Packaging

- Optimizing energy flows (condensate recycling)

- Format-specific settings (energy reduction)

- Maximum consumption << 60% compared to existing market standards

Home Specialties CombiSteam FB80 – AGV100

CombiSteam

FB80 – AGV100A micro-line for short production chain and direct distribution in dairy markets.

Features

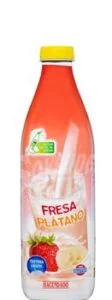

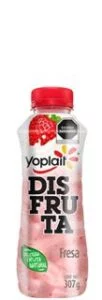

The eco-design of packaging for local market distribution.

An equipment that aligns with the eco-design of the products

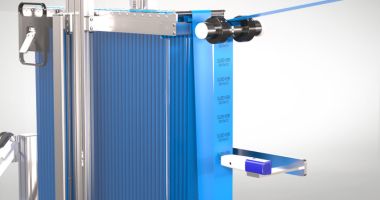

A compact all-stainless steel monobloc structure integrating: dryer, application head, shrink tunnel, electrical cabinets integrated into the frame, and a steam generator. The modular design enables the handling of a wide range of products, from jars to bottles, in PET and HDPE, with multiple capacities and shapes.

The modular machine for multi-formats

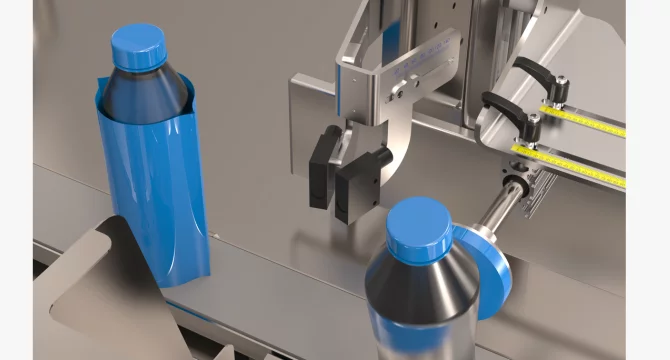

Ease of implementation for various shapes.

With its modular design, this machine can accommodate multiple product formats. Designed with modularity in mind, this machine accommodates various product formats. Tooling is designed for easy, tool-free, and adjustment-free interchangeability. Operators have complete autonomy and can change formats within minutes, assisted by a central HMI and tutorials accessible via QR codes.

Recyclability of energy streams and minimalist consumption.

Steam shrink tunnel with controlled energy consumption

The steam shrink tunnel, with its unique and innovative design, ensures optimized energy consumption through the combination of three key elements: a lift system, a range of steam diffusers, and an expansion chamber tailored to each product, all managed centrally from the 12-inch HMI.

Integrated electric steam generator.

Minimizing carbon footprint.

Integration of the steam module along with its water treatment system:

Options

A guaranteed and constant level of quality

Multiple checks for a product of high quality

Master your format changeover times with the carrying trolley.

Tool trolley for your multiple formats

When traceability and unit marking are required by the markets.

Marking and serialization module as an external component to the equipment.Specifications

* Non contractual information

Machine

Conveyor height980 +/- 50 mmSpeed100 bpmCutting diameter130 mmSteam consumption100 Kg/hSteam pressure6 – 8 barsElectrical consumption12 kWHMachine length5720 mm

Packaging

MaterialsPET, PEHD, PP, glassShapesCylindrical, oval, advancedProducts diameter35 to 128 mm (jars, bottles)Product height245 mmSizes80g to 800g - 20cl to 75cl

Sleeves

ApplicationFull bodyType of filmsPET, rPETFilms thickness30 – 50 micronsMarkets & Packaging

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.Statistics

The technical storage or access that is used exclusively for statistical purposes. The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.