- Group

- A horizontal application adapted to unstable packages, small formats and sophisticated and varied shapes

- Total tamper resistance with protection and security features

- An ergonomic design for frequent and quick format changes

- A combination of performance and quality finish

- Features

- Options

- Specifications

- Packaging

Home Turnkey Sleeve Equipment Multiflexshrink® TE130 – AI20

Multiflexshrink®

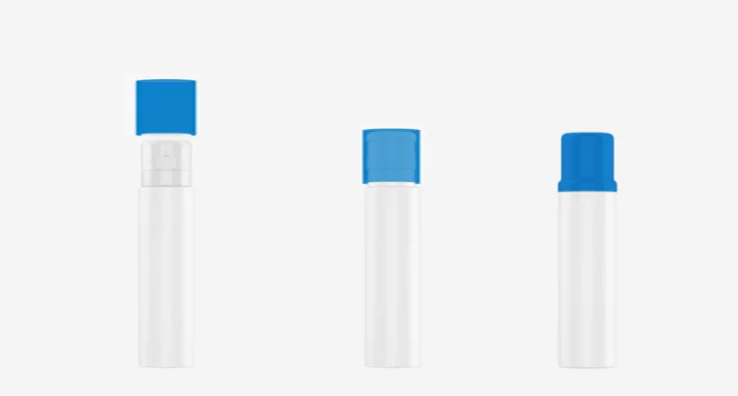

TE130 - AI20Tamper evidence for small food formats and household products

Features

A horizontal application technology suitable for small and unstable formats

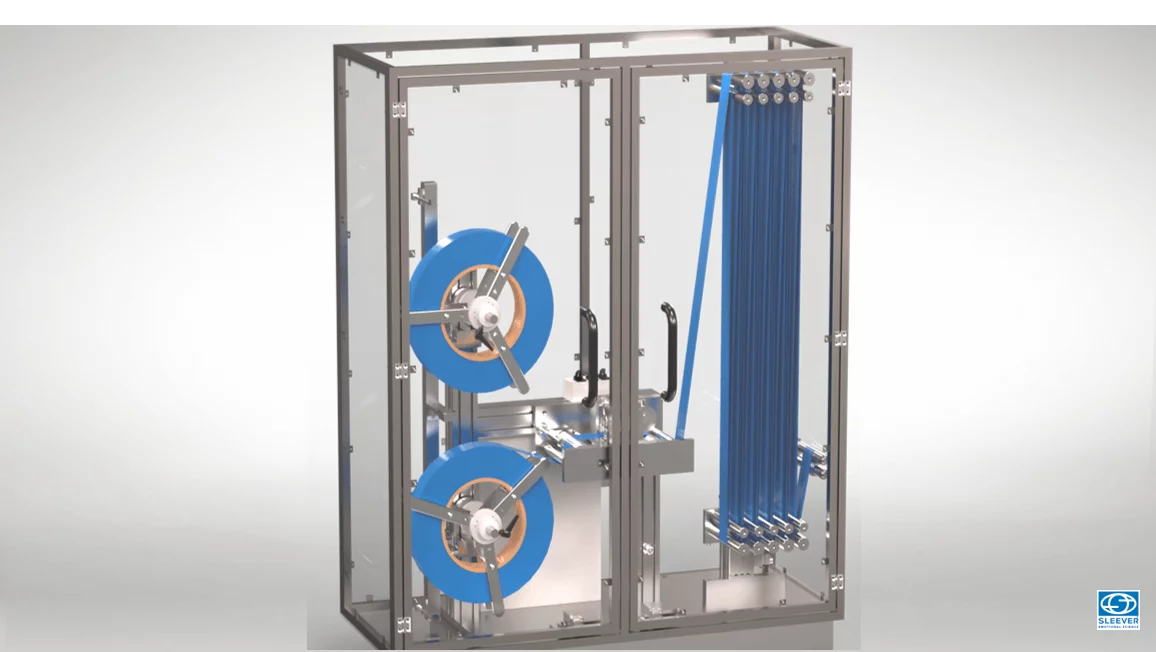

An ultra-compact machine specifically adapted to the small and unstable formats of confectionery and household items

Its design and horizontal application technology meet the security needs of confectionery, DIY and homeware brands for their small and unstable formats. Its very compact size, less than 7 feet long, allows for optimal floor space and fits into any workshop. It consists of a single chassis and includes the horizontal application, the infrared/hot air shrinkage applicator and the integrated electrical cabinet.

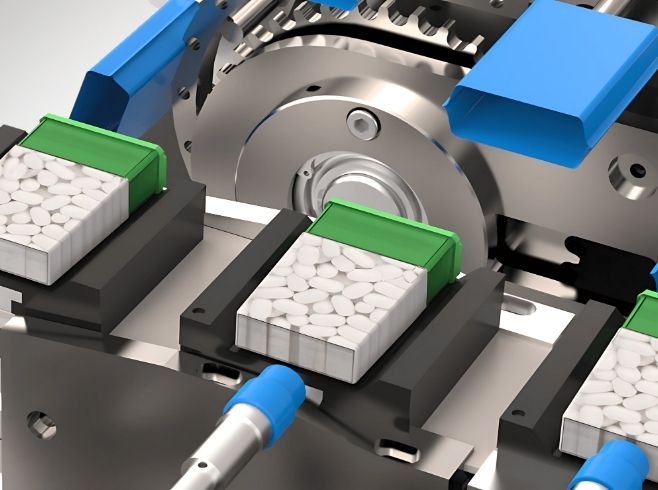

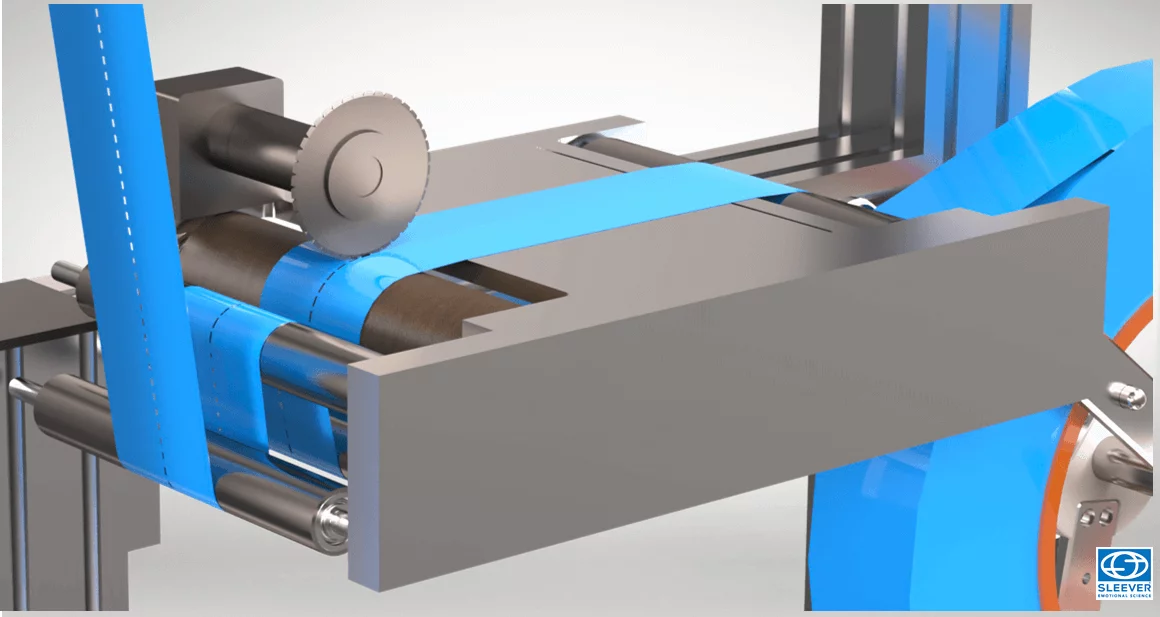

A closed-cells conveyor protects the products

Increased security thanks to full product protection

During the application process, the product is fed flat onto a closed-cells conveyor where it is maintained regardless of the complexity of its shape or the speed of the machine: after transferring it to the inside of the shrink-sleeve, it is fully wrapped for complete protection and enhanced security.

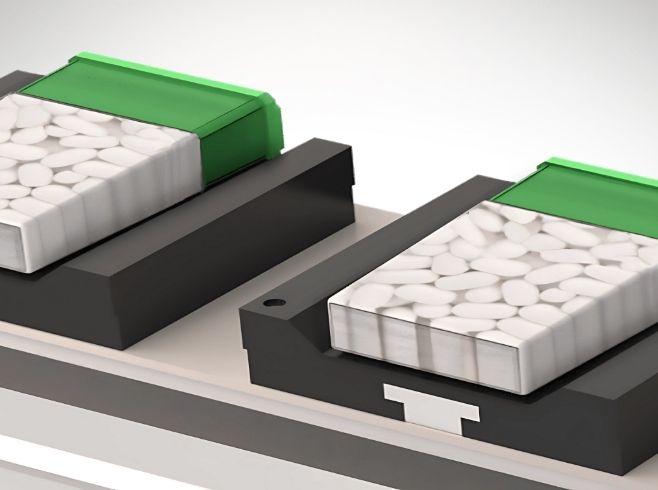

Ergonomics and flexibility for fast restarts

An ergonomic design for easy changeovers

Everything has been designed to promote flexibility and optimize format changeover times, which are common in the confectionery and object markets. Each format has its own toolkit that can be replaced without any tools, such as the retractable honeycomb blocks on the conveyor. The settings are stored in the PLC and memorized on the interface, which makes the operator’s work easier. Changes can be made in just a few minutes and the restart is immediate. Ergonomics is ensured by easy access to every part of the machine.

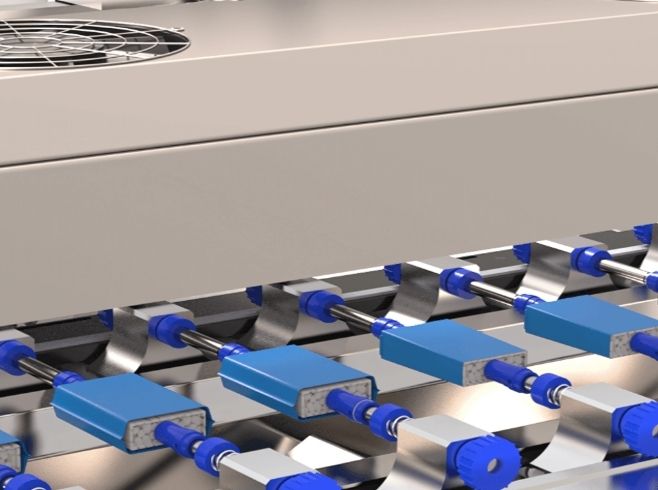

Performance and high-quality finish

A technology that does not compromise on speed while ensuring a quality finish

The quality of the finish is guaranteed thanks to a gripping system that keeps the products rotating while continuously advancing under the infra-red ramp ensuring the shrinkage of the shrink-sleeve label: in this way, the product is not in contact with the conveyor at any time and therefore avoids any risk of damage. This technology combines quality with high speed up to 130 cpm.Options

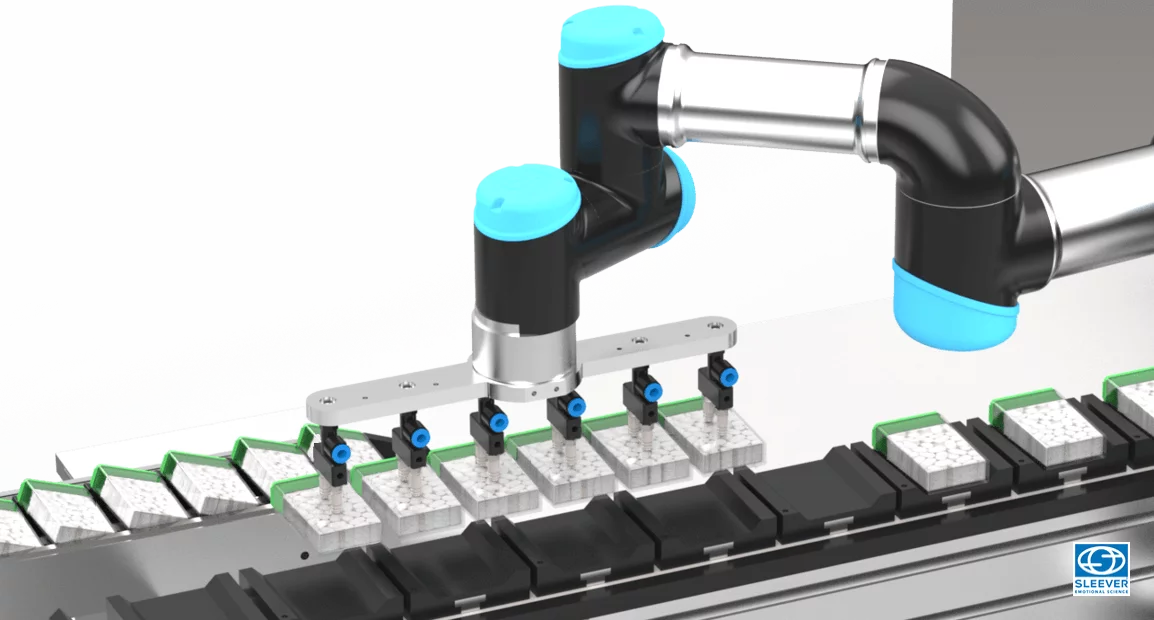

Automatic loading module

Automatic loading: a tailored solution for your performance

Large capacity shrink-sleeve unwind unit

Large capacity unwind unit for increased autonomy

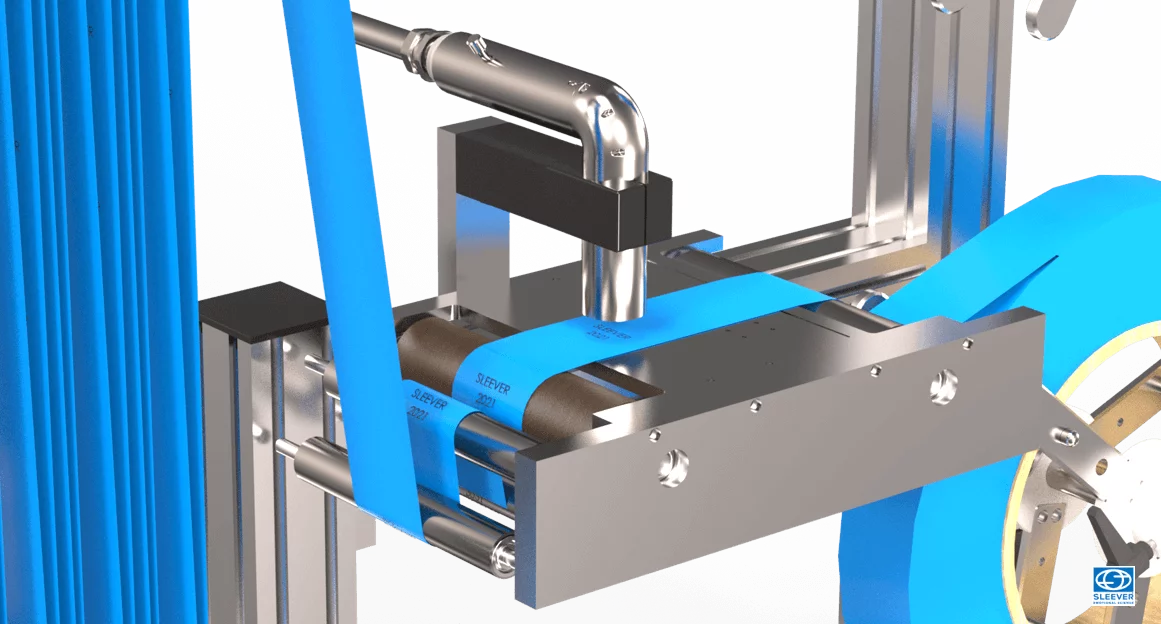

Coding module

Ensure the traceability and serialization of your products

Micro-perforation in line

In-line micro-perforation for increased flexibility and consistent qualitySpecifications

* Non contractual information

Machine

Conveyor height960 mmSpeed130 cpmCompressed air6 barsElectrical consumption20 kWMachine length2540 mm

Packaging

MaterialsObjects , plastics, metalShapesCylindrical,square, hexagonal, oval complex shapes...Sizes20ml - 1LProducts diameterFrom 4 to 30 mmProducts heightFrom 65 to 150 mm

Sleeves

ApplicationTamper evidenceType of filmsPET, RPET,OPSFilms thickness40 to 90 micronsFinishingneutral, printed...Markets & Packaging

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.Statistics

The technical storage or access that is used exclusively for statistical purposes. The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.